GARDINER — Rum brings to mind tropical flavors, crushed ice and little paper umbrellas.

None of those things is in evidence anywhere in the Sebago Lake Distillery in Gardiner, where production of the company’s very first rum is underway. Instead, it’s all business at 463 Water St., with the big copper-clad still in a cavernous room at one end of the distillery building cooled with an industrial-sized fan.

The clear liquid that’s decanting from the still into a quart-sized mason jar is the focus of three years of planning, investing, applying for licenses, tweaking recipes, waiting, and then waiting some more.

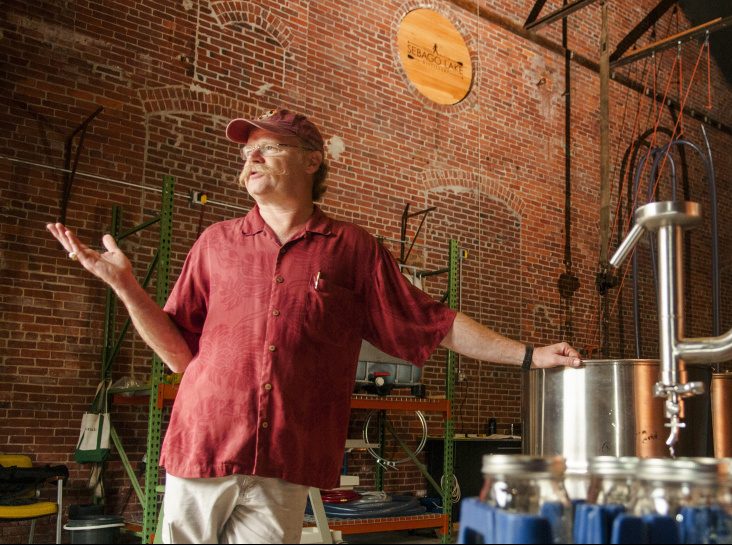

“You have to have patience,” said Dave Tomer, one of the partners behind Sebago Lake Distillery. The partners all own or run other businesses and bring those skills to this pursuit.

While assembling a small glass still, Dan Davis talks about the herbs and spices he added to the rum to produce gin-type flavors when distilled again.

When the operation hits its stride, it will be yet another piece of Gardiner’s economic shift to becoming a regional food hub. For decades, mills took advantage of the harnessed power of Cobbosseecontee Stream to make a variety of products, including paper and wool, and employ people from Gardiner and across the region.

From the void left behind when the mills closed, another idea emerged.

“Gardiner Main Street has identified several key transformational strategies, and capitalizing on the local food and craft beverage industry is a key component,” said the group’s executive director, Patrick Wright.

Gardiner Main Street’s focus is fostering economic and cultural vitality. In recent years, Gardiner has attracted businesses such as Central Maine Meats, a USDA-inspected meat processing facility, and Maine Cap N’ Stem, which sells organic gourmet mushroom blocks, in a bid to give the southern Kennebec County city a new direction.

“One of the things that has impressed me from the first meeting with Sebago Lake Distillery is they seem to be well organized in their thoughts and plans,” Wright said. “Even though some components of the plan have changed, they have the vision to develop a great product and marketing scheme.”

Through the city of Gardiner, Sebago Lake Distillery has applied for and received $90,000 in economic development funding through the Community Development Block Grant program. The partners used the money to hire workers sooner than it otherwise could have. Under existing regulations, distilleries must secure a site and install a still before a distillery can start operations. That means the company has to start paying workers long before any product can be made or sold, and the economic development grant money helped bridge that gap.

Although craft distilleries have been springing up in central and southern Maine, Tomer said his research shows that there’s a gap in the market that can neatly be filled by a quality sipping rum.

Rob Lash checks temperature gauges on a still. Distilling requires patience, an understanding of what occurs during the fermentation process and a sense of what makes a good product.

Rum has figured prominently in Maine’s past.

Dan Davis, master distiller of the Gardiner operation, said rum developed with the trading and settlement forays into the New World that resulted in growing sugar cane in the West Indies. As the commodities trade in lumber and sugar started developing among Europe’s holdings in North America, a spirit made with cane sugars was the result.

“It is said that Maine rum saved the Revolution,” Davis said. “George Washington was stuck in Valley Forge without supplies, and a shipment of Maine rum got through and gave them the spirit they needed to continue.”

Distilling mixes science and art. It takes patience, an understanding of what happens during the fermentation process and a sense of what will make a good product.

Davis still is experimenting and working to perfect what will be the rum that Sebago Lake will sell. He said he’s very close.

This week, a film crew from Tennessee was in Gardiner, capturing video and stills for marketing materials, social media and the company’s website, which is still in development.

When all that’s done, there still will be work to do.

The bottles will have to be labeled and shipped out, and because the liquor industry is heavily regulated, there will be paperwork to fill out and file.

Tomer estimates the rum will be ready for sale in October, but he and his partners are looking past that date to what’s next – filling the tasting room and finding a way to reach into the state’s tourism industry.

“We’re not chasing the almighty dollar,” Tomer said. “We’re chasing a way of life.”

Jessica Lowell can be contacted at 621-5632 or at:

jlowell@centralmaine.com;

Copy the Story LinkSend questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.