Falcon Performance Footwear’s boots are expensive, no one knows about the company, and it faces competition from higher-volume rivals. And President Carl Spang sees those as strong points for the Auburn-based bootmaker.

“Word of mouth is our best ambassador,” Spang said. “Until they know you and know what the boots are capable of, it makes it a tough sell. But once we have a customer, they tend to be very loyal.”

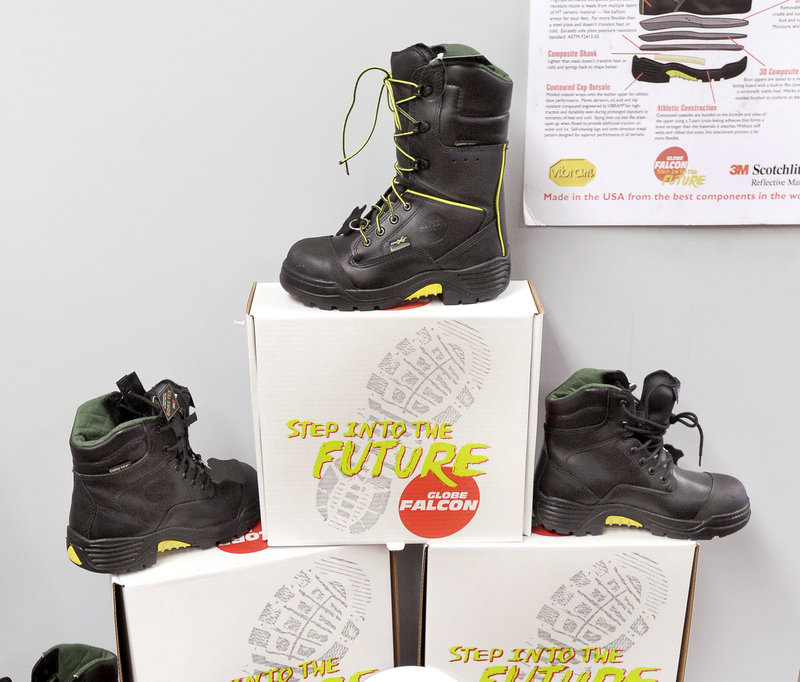

Falcon makes 60,000 pairs of high-tech industrial and firefighting boots a year and is expanding capacity by 20 percent annually. It’s shying away from being a mass manufacturer that must survive on razor-thin margins.

“There’s another model of chasing cheap labor, trying to make up in volume what you’re losing in margins, and that business model has driven business out of the U.S.,” Spang said. “That’s not us. Instead of looking at unit costs, we look at total costs. And it’s actually cheaper for us to make our boots in Maine.”

Since buying Falcon in 2007, Spang has been shifting more and more of the material production to Maine. He’s got just two pieces left to go before the boot is 100 percent sourced and made in the state.

Falcon is working with the University of Maine and the Maine Technology Institute to develop the materials to replace the two components — materials that line the footbed — that currently come from Taiwan and China.

“There’s an amazing ripple effect when you buy the materials in Maine, employ workers here to make the boots, and they spend their income in Maine. It creates a much more solid economy,” Spang said.

The boots, which can handle extreme temperatures from 20 degrees below zero Fahrenheit to 140 degrees above, can be custom made and modified to fit orthotics or special sizing. The boots have a running sole footbed, giving users more agility and comfort in tackling various terrain. They come at a cost, though. The boots start at $285 a pair.

“They’re worth it. I spend 12 to 14 hours a day in my boots. I’m on my feet all day long. I’ll never wear another boot,” said Dan Landers, who works as a maintenance supervisor at a printing plant in Lewiston.

Landers, who has worn Falcon boots for about a year, credits the special technology in the boot that stiffens on impact with saving his foot from a serious injury recently. Landers was moving equipment at the printing plant when a 500-pound cabinet fell on his foot. The metatarsal guard in the boot, which is flexible but stiffens when hit, protected the top of his foot, Landers said.

“If I had been wearing another type of boot, my toes might have been OK, but the bones on top of the foot would be broken,” Landers said. “All I had was a red spot the size of a quarter and I’m walking today without a limp.”

Spang sees the boots as more than footwear — they’re a high-tech safety system, he said.

Radio-frequency identification systems can be embedded in the mining boots to help track and locate workers. Spang sees future technology options for the boots, such as installing a chip to monitor when a worker enters and leaves the job site, in order to eliminate the need for workers to stand in line to clock out at the end of their shift.

Spang explodes with enthusiasm about the potential for the boots and the possible uses of the components’ technology.

For example, the toe covering for the boot is made of a fiberglass and resin composite material that doesn’t conduct electricity or heat, making it a safer alternative in many industries than steel-toe boots, he said.

The material was developed through work with the University of Maine researchers, a grant from the Maine Technology Institute, and a $180,000 investment by Falcon, Spang said.

In addition to potentially making toe caps for other footwear manufacturers, Spang sees the high-tech composite material eventually being used in the avionics and maritime industries.

Such applications may be two to three years away, but Falcon is in talks to use its toe cap material in high-tech components outside the footwear industry.

The U.S. military also has expressed interest in the high-tech toe caps, but Spang said that level of production would mean too much growth for the 54-employee business.

“We have to be very careful not to kill ourselves at the same time,” Spang said.

Falcon has been careful to grow in a measured way. It also has made forays to expand internationally to Canada and Chile, and potentially Brazil and Colombia down the road. Falcon’s also benefited from an increase in mining activity in the U.S. due to high commodity prices for precious metals.

Falcon’s ability to see different applications for its footwear technology and leap to expand internationally helped the company garner the Innovator of the Year award from the Maine International Trade Center.

“I’m the least knowledgeable footwear person in the room,” Spang said. “And sometimes that helps.”

Spang’s background is in the computer industry, working at Digital Equipment Corp. and Sun Microsystems, and in lean manufacturing systems. He brings a different perspective to the company and helped introduce a new manufacturing layout and system that cut the time to make a boot to five days from 20 days.

Falcon started manufacturing children’s shoes in 1963, but it shifted its focus to work boots in 1990. Spang and Globe Firefighter Suits bought the company in 2007, and forged an alliance to design and produce firefighter footwear. It introduced the mining boot two years later.

“We’re pioneering new materials. We’re leading these niches in advanced safety technology,” Spang said. “We’re not a high-volume company.”

Staff Writer Jessica Hall can be contacted at 791-6316 or at:

jhall@mainetoday.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.