A Maine business that recycles used cooking oil into a clean-burning fuel will benefit from an obscure piece of the “fiscal cliff” legislation that Congress passed Tuesday.

Tucked into the 157-page bill to avert federal spending cuts and some tax increases was language that reinstated a $1-a-gallon tax incentive for producers of biodiesel in 2013, and made it retroactive to January 2012. The National Biodiesel Board estimates that the credit will help support 112,000 jobs and boost production this year.

More jobs and gallons are in the forecast at Maine Standard Biofuels in Portland, the state’s only commercial biodiesel plant.

The tax credit will help the company buy a second truck to collect used fry oil and expand its 11-person staff. The plant now produces 300,000 gallons a year, but is capable of 1.5 million gallons.

“The demand for biodiesel is there,” said Jarmin Kaltsas, the company’s president. “Everything we produce is out the door as quickly as we can make it.”

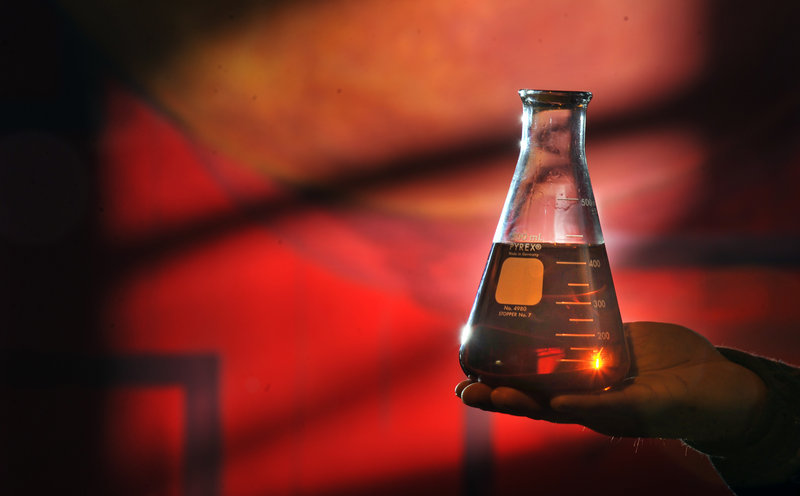

Biodiesel is made using a chemical process that separates glycerin from vegetable oil and animal fat. Diesel vehicles and furnaces that burn heating oil can run on biodiesel, or a blend with petroleum diesel.

Fuel-grade biodiesel, like what’s being made at Maine Biofuels, is certified to meet strict performance standards.

In the past five years, a growing industry has evolved in response to government regulations aimed at cutting petroleum use and reducing emissions linked to air pollution and climate change. Production is centered in the nation’s farm states, where soybeans and other crops are used as raw materials for biodiesel.

That’s why the tax credit, first passed by Congress in 2005, got a strong push from influential farm state lawmakers such as Sen. Charles Grassley, R-Iowa. It also won support from Sen. Susan Collins, R-Maine.

“Federal incentives such as this have a tangible economic impact that can help companies increase production and hire new employees,” Collins said in a prepared statement. “Biodiesel, like Maine Standard Biofuels’ recycled waste cooking oil, is helping to provide a homegrown, alternative energy solution to power diesel engines and heat homes, which reduces emissions and America’s dependence on imported petroleum.”

In Maine, the raw material for biodiesel is almost entirely fry oil from restaurants.

Maine Standard Biofuels operates in an industrial park on the outskirts of Portland. It has been growing slowly since 2006, and now collects oil from 500 restaurants from Bar Harbor to Boston.

But that’s only about 15 percent of the area’s potential “feedstock.” Kaltsas estimates that Maine restaurants generate 1.2 million gallons of used fry oil a year — a gallon for nearly every resident.

Come summer, when tourists are wolfing down fried foods, the volume increases. For instance, DiMillo’s on the Water, a restaurant on the Portland waterfront, generates roughly 25 gallons of used fry oil a week at this time of year, and 75 gallons a week in the summer.

The restaurant used to send its used fry oil to an out-of-state recycler, at a cost. Now, Maine Standard Biofuels picks it up and pays for it.

Grease is a valuable commodity these days, listed on the Chicago Board of Trade.

“They pay us top dollar for waste oil and they’re doing good things,” said Steven DiMillo, the restaurant’s manager. “It works out great and it fits into our green efforts.”

Kaltsas started Maine Standard Biofuels with a bank loan, and has since attracted investors.

Inside the $2 million plant, a production line turns fry oil into pure biodiesel. Along the way, equipment settles and filters food waste, then removes the glycerin byproduct so it can be used for soap-making or composted.

Methanol that’s used in the process is recycled in a closed-loop system.

Outside its plant off Riverside Street, the company operates a retail pump on weekdays to fuel up diesel cars and trucks.

Kaltsas has marketed his product to fleet owners that want to use a local fuel and reduce their dependence on oil. Major customers include Oakhurst Dairy, L.L. Bean, Barber Foods, Paradigm Windows and Downeast Duck Adventures.

Oakhurst Dairy, the largest user, blended 140,000 gallons with petroleum last year to run 70 tractor-trailers and 80 trucks.

“It’s a very good product that’s manufactured locally,” said David Green, Oakhurst’s fleet manager.

Pure biofuel gels in cold temperatures, so it’s blended with varying levels of petroleum. In the summer, Green has been able to run the dairy trucks on as much as 70 percent biofuel.

For home heating, biofuel typically makes up 20 percent of the blend. The price of bioheat, as it’s called, is often a little above that of heating oil.

Maine Standard Biofuels began delivering to heating oil customers in Greater Portland last year. It was charging $3.40 a gallon on Thursday, on par with regular heating oil.

Maine Standard Biofuels also has been lining up distributors and oil dealers that want to blend and market locally produced bioheat.

In Rockport, more than half of the customers of Harvest Energy burn bioheat, said Steven Young, the general manager. The cash price is $3.79 a gallon, a dime more than regular heating oil.

People like the fact that bioheat burns cleaner, he said, but the sour economy has slowed growth. He expects growth to resume as the economy recovers.

The revived tax credit is giving a boost to the biofuels industry, which remains a risky venture.

Two plants in central Maine have closed in the past few years. And there’s no assurance that the tax credit will endure — Congress allowed it to lapse in 2010 and 2012.

Kaltsas said that although he expects new plants to be built on the strength of the tax credit, his business model assumes slow growth and no subsidy. Buying used oil solely from restaurants, rather than receiving shipments pegged to the commodity market, is keeping costs stable.

“There’s still a lot of room for growth here,” he said.

Staff Writer Tux Turkel can be contacted at 791-6462 or at:

tturkel@pressherald.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.