SOUTH PORTLAND — There’s a faded poster on the wall of the Portland Pipe Line Corp.’s control room here with the heading: “Why Shut Down a Pipeline?”

Nine reasons are listed, including the detection of a leak and unexplained pressure changes. It also reads, in big letters: “The Full Authority is Yours.”

That message is aimed at the controller, whose decisive action — perhaps alone in the middle of the night — could make the difference between a destructive oil spill and a routine procedure.

The poster may be old, but its words convey a new urgency.

Pipeline safety has become a front-page concern, thanks to an extensive international campaign by environmentalists opposed to the production and movement of so-called tar-sands oil from Alberta.

The campaign has highlighted a disastrous accident in Marshall, Mich., where a pipeline carrying heavy crude from western Canada burst in 2010, releasing 20,000 barrels of oil into the Kalamazoo River and adjacent floodplains. Controllers at Enbridge Inc., which owns the pipeline, ignored repeated alarms and didn’t turn off the pumps for 17 hours, according to the National Transportation Safety Board, leading to the largest onshore spill in U.S. history.

The Enbridge mess is still being cleaned up today. That fact, and a pending decision by President Obama about whether to approve the Keystone XL pipeline from Alberta to the U.S. Gulf Coast, have led to unprecedented scrutiny on how the nation’s petroleum pipelines are operated.

Public interest is likely to intensify, following Friday’s rupture of an Exxon Mobil pipeline in Arkansas that was carrying heavy crude from western Canada. Crews had cleaned up 12,000 barrels of oil and water by Sunday, and no cause has yet been made public. The leak forced the evacuation of 22 homes in a subdivision, according to news reports.

In northern New England, the Portland Pipe Line Corp. has compiled an impressive safety record in 72 years of operation. Yet the company finds itself under an intense public microscope. Interest has been magnified by fears — highlighted by environmental groups — that Portland Pipe Line is preparing to pump tar-sands oil through its system.

Tar-sands oil has become an international rallying cry for environmental activists, who say fully developing the resource will vastly speed up climate change. They charge that the oil forced from massive underground sand deposits in Alberta is especially corrosive to pipelines and that its properties make it harder to move and clean up. The industry counters that the oil is no different than the heavy crude it has safely transported for decades.

In Maine, the Portland pipeline operators have hurt their public relations efforts by issuing confusing, equivocal pronouncements: There’s no active project to reverse the flow of its lines and move tar-sands oil from Alberta to Portland Harbor, they repeat, but to boost sagging business and maximize the company’s assets, they are exploring the market potential.

At the same time, though, the company has earned credibility with a solid safety record. Since 1941, it has pumped more than 5 billion barrels of crude oil from South Portland to refineries in Montreal, through a 236-mile underground pipeline. Very little of that oil has escaped into the environment. The largest spill, 26 years ago, was 2,500 gallons.

LIMITING THE RISK OF A SPILL

This performance has earned the company high marks from government regulators and industry trade groups. Its quiet competence has made the pipeline a good neighbor to most residents, although for security and other reasons, the company typically reveals little about its day-to-day operations.

Following a request earlier this month, the Maine Sunday Telegram received exclusive permission to observe and report on control room operations while a ship was unloading to the tank farm, as oil was flowing to Montreal, and when workers were performing a key maintenance job meant to assure the integrity of the pipeline.

These activities help show how pipeline companies limit the risk of a spill, although the strategies aren’t foolproof. The draft of a recent study done for the federal Pipeline and Hazardous Materials Safety Administration found that control room operators identified leaks in hazardous liquid lines only 17 percent of the time. It concluded that air patrols and ground crews inspecting the lines were more likely to find problems.

The industry, represented by the American Petroleum Institute and the Association of Pipe Lines, has responded that the study’s contractor relied on academic discussions and technology vendors, without using real-world data. The industry says it’s planning new research on advanced, in-line inspection and crack detection tools.

But the Enbridge disaster has highlighted that it takes more than new technology to detect and react to leaks. Federal investigators concluded last year that the failure of control room operators in Alberta to correctly respond to repeated leak alarms reflected a “culture of deviance” about following company procedures.

In South Portland, the company’s training and operating procedures contain the expectation that controllers will shut down if they even suspect that something abnormal is taking place, according to Tom Hardison, director of operations and maintenance.

“The important thing is to shut down first, and determine what you have from there,” he said. “Controllers don’t have to ask anyone for permission to do that.”

The HS Elektra, a 802-foot crude oil tanker, was docked at the marine terminal’s north pier. The tanker had arrived on the morning high tide, March 9, with roughly 700,000 barrels of crude oil from the North Sea. Fourteen hours later, the ship would be empty.

OIL MUST MEET STRICT CRITERIA

The pipeline is designed to handle oil from all over the world, but not every load is accepted. Crude that’s not on a list approved by the company must be nominated by shippers and meet strict criteria for properties that include viscosity, vapor pressure, sediment and chemical elements, such as sulfur.

Even then, the oil doesn’t go straight into the pipeline. It’s stored among the 23 tanks at the South Portland tank farm and sampled in a lab. No load, for instance, can contain more than 1 percent sediment.

“Anything that’s accepted into our system has to meet these criteria,” Hardison said. Critics say the abrasive sediment in heavy, tar-sands oil is tough on pipe walls, putting them at a greater risk of failure. But Hardison said the company would never subject its multi-million-dollar pumps to a destructive load, any more than someone would pour sand into their car’s engine oil.

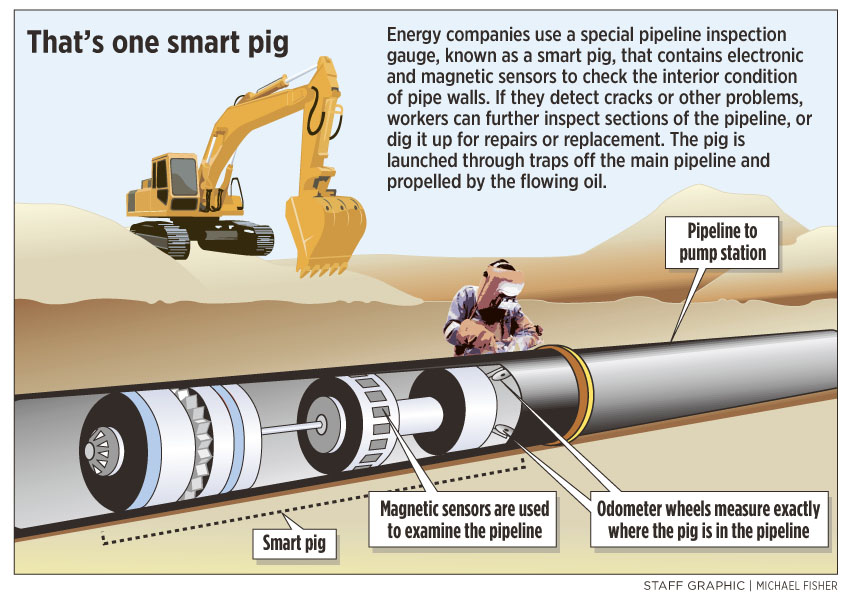

It’s inevitable, though, that some sediment and mineral deposits will settle in a crude oil pipeline, where they can contribute to corrosion. To clean its line, the company relies on a “pig.” A pig is a term for a cylindrical tool nearly the diameter of a pipeline. Early models made of straw and wire apparently made a piglike, squealing noise.

Every three months, a brush pig is stuffed into a pipeline in South Portland to ride underground on a stream of pressurized oil to Montreal.

The pig used at the Portland-Montreal pipeline weighs 100 pounds. It is tipped with plastic cleaning cups that scoop out water and sediment. A plastic drive cup seals the pig inside the pipeline to allow oil pressure to propel it along, while spring-loaded, metal brushes scrape and clean the walls.

Earlier this month, three workers set up a pigging operation to clean the company’s 24-inch-diameter, coated steel line. They lifted the brush pig into an elbow off the main pipeline, called the scraper launching trap. Then they used a ramrodlike metal pole to stuff the pig into the mainline, and resealed the pipe. Oil introduced behind the pig sent it on its way.

In a little over two days, the pig would be in Montreal, where workers would grab it from the receiving trap. Typically, the pig will push out a few gallons of a waxy buildup from the pipe walls.

“In most places, the pipe is in excellent condition because of this cleaning regimen,” Hardison said.

To assess that condition, the company relies on a “smart pig.” Smart pigs contain electronics and other sensors that can detect and measure pitting, corrosion, cracks and weld defects. An odometer records the location of these potential problems.

A five-year study by the Association of Oil Pipe Lines found that the overall number of spills on segments tested with smart pigs dropped by 50 percent.

The Portland Pipe Line Corp. has used this technology since 1981. It does the internal inspections at five-year intervals; the last was done in 2012.

Smart pigs have found “anomalies” that led the company to inspect, replace or repair sections of pipe, Hardison said, although the company declined to provide specific examples or details.

Taking action when an anomaly is discovered is a critical follow-up. In Michigan, investigators traced the Enbridge rupture to a 6-foot-long gash caused by corrosion and fatigue cracks that were detected in 2005, but not inspected further or repaired.

The Portland-Montreal pipeline is actually three parallel lines. The original 12-inch-diameter line was installed in 1941 to supply crude oil to Canada during World War II. That line was taken out of service in 1982.

An 18-inch-diameter line was constructed in 1950. It is currently idle due to lack of business and filled with nitrogen gas, which displaces oxygen to prevent internal corrosion.

The 24-inch line was built in 1965. It can handle up to 410,000 barrels of oil a day. Both steel lines are coated with coal-tar enamel to fight external corrosion. They also receive cathodic protection, a common practice for underground pipelines in which a more-easily corroded metal is sacrificed with the aid of an electric current.

All oil movement is coordinated through a control room located in a high-security section of the tank farm. The company uses supervisory control and data acquisition, or SCADA, a hacker-resistant, industrial software program that gathers data in real time from remote locations. The program monitors eight pumping stations that move the oil from South Portland to Montreal: three in Maine, two in New Hampshire, one in Vermont and two in Quebec.

OIL TEMPERATURE AT ISSUE

On the day the HS Elektra was in port, Peter Fickett was sitting in front of six computer screens, where he could follow the oil’s journey.

The first screen displayed a schematic of the oil’s flow path from the pier to four waterfront storage tanks. The second screen showed the flow from storage tanks and the associated valves and manifolds.

Screens 3 and 4 showed the status of the 18-inch and 24-inch lines as they passed through the pump stations and under the St. Lawrence River. They display all the operating data for the pipeline, including the oil pressure and temperature at each station. On this winter day, the oil temperature in South Portland was 52 degrees. It had fallen to 45 degrees at the Raymond pump station, 26 miles away.

Activists charge that tar-sands oil travels at high temperatures through pipelines, but Hardison said that’s not possible in an underground, uninsulated pipe in northern New England.

“After the first 26 miles, it’s at ambient ground temperature,” he said, “and it stays the same until Montreal.”

The Portland-Montreal pipe line also can’t operate at high pressure, Hardison said, because of its design specifications. Protective devices, acting like electrical circuit breakers, keep the flow below a maximum allowed operating pressure.

A fifth screen monitors the tank farm and an oil refinery in Montreal, while a sixth screen graphs pressure drop over distance. This last screen employs Computational Pipeline Monitoring, a software tool that uses algorithms to help detect leaks. It calculates specific gravity, pressure and other inputs designed to make sure the volume of oil delivered to Montreal is the same as what went into the line in South Portland.

Fickett said he can shut down the pipeline within five minutes. Emergency shutdowns are rare, however, and Fickett hasn’t seen one in four years on the job. Last month, as a precaution, the pipeline was shut down following a complaint about the smell of oil at a house near the right-of-way in Raymond. The homeowner called the pipeline company and the fire department.

“That’s all the controller needed, and down it went,” Hardison said. “He doesn’t have to call anybody.”

The problem turned out to be a faulty propane furnace.

Tux Turkel can be contacted at 791-6462 or

tturkel@pressherald.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.