BATH — With Saturday’s christening of the last-in-a-series Arleigh Burke-class destroyer, shipbuilders at Maine’s Bath Iron Works are turning more of their attention to construction of a larger, stealthier and more expensive warship that will be like no other built at the shipyard.

The shipyard is wrapping up the original production run of Burkes as it shifts production to three next-generation destroyers, the largest surface warships to be built in Bath.

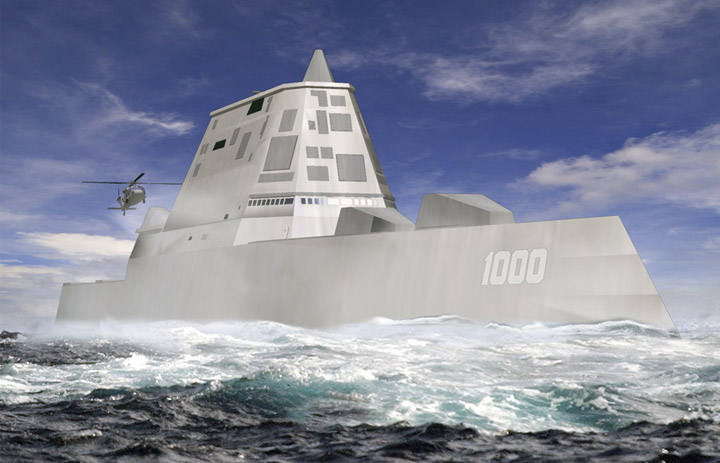

Already under construction, the DDG-1000 Zumwalt features composite materials, electric-drive propulsion and an unconventional wave-piercing hull. Displacing about 14,500 tons, the ship is 50 percent larger than Burkes but, thanks to automated systems, will have half the crew.

It’ll also carry a heftier price tag: The Zumwalt will cost at least three times more than the $1.1 billion spent on the future USS Michael Murphy, which was christened Saturday.

Shipbuilders are uneasy because the shipyard and the Navy haven’t signed off on contracts for the remaining two Zumwalts. All three are needed to avoid big layoffs at the Bath shipyard, which employs 5,500 workers.

“It’s a matter of survival for us,” said Dan Dowling, president of Local S6 of the Machinists union. “If we don’t get those two, then we’re going to be in some deep trouble.”

The Murphy, named for a Navy SEAL officer killed in Afghanistan, was the last in the current run of 62 Arleigh Burke destroyers, which began production in the 1980s.

There’s currently only one other Burke-class destroyer at the shipyard — the Spruance, which already has been delivered to the Navy. It’s a far cry from the days when there were a half-dozen destroyers in various stages of construction at the General Dynamics subsidiary.

Out of view from the public, however, work is already under way in the enclosed Ultra Hall on the Zumwalt, which doesn’t yet resemble a ship. The Ultra Hall is the shipyard’s tallest assembly building, created to assemble the giant pieces of the 600-foot Zumwalt.

“You cannot help but be impressed by the size of those things,” said spokesman Jim DeMartini, who noted that the Zumwalt is about 40 percent complete.

The low-slung warship with a futuristic-looking composite deck house was conceived to move close to shore and pound the beachhead with special 155 mm guns that can hit targets from 100 miles away, paving the way for the Marines to go ashore.

From the start, the biggest problem was the cost. The Navy truncated production to only three ships after estimates for the first ship grew to $5 billion or more.

“Nobody argues with the mission. It’s just the dollars it took to get there,” said Jay Korman, defense industry analyst with The Avascent Group. “It’s too expensive for the times.”

The Navy considered basing its next-generation cruiser on the Zumwalt before abandoning that project altogether. Instead, the Navy decided to restart production of the tried-and-true Arleigh Burke-class destroyer upon completion of the Zumwalts.

The Navy intends to replace or upgrade missiles, computers and software, and to make other changes to make the Burkes more capable. Many of them will see upgrades to their Aegis defense system allowing the warships to be used for ballistic missile defense.

“The Navy now has a stable plan for using Burke destroyers all the way until mid-century,” said Loren Thomas, analyst with the Lexington Institute.

After a brief hiatus in production, the Bath shipyard and the Ingalls shipyard in Pascagoula, Miss., will resume production of the Burkes. At least three more of them will be built, two of them at Ingalls and one at Bath.

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.