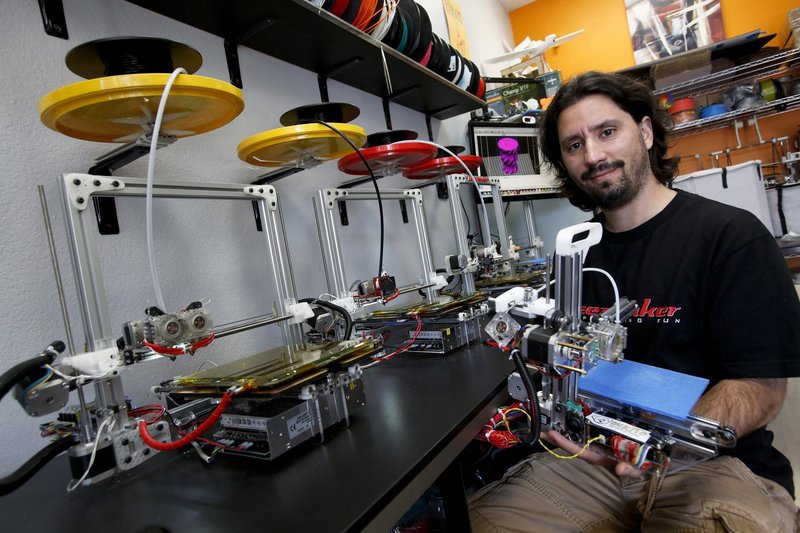

Diego Porqueras’ Deezmaker store in Pasadena, Calif., is a geeky version of Santa’s workshop, brimming with action figures, chess pieces and jewelry.

But instead of relying on elves, Porqueras has built his own one-man factory using 3-D printers capable of churning out plastic objects within a few hours. He sells the printers, which go for as little as $650, at the shop, which opened in September in a strip mall.

The 37-year-old entrepreneur is part of an emerging industry for affordable 3-D printers. The technology has long been used in the aerospace and automotive industries, among others, to create prototypes, but has slowly crept into the consumer market with simplified printers that can be had for a few hundred or thousand dollars.

“You can make so many things with them,” Porqueras said. “People who have businesses buy them for making prototypes. Parents buy them to make toys for their kids. Hobbyists buy them because they like to tinker.”

3-D enthusiasts imagine a day when these printers are as ubiquitous as phones and people print out many household goods instead of stopping at a store. Small-business owners are already switching to these printers from more expensive industrial machines. Prices are expected to drop even further after key patents on 3-D printing technology expire next year.

Usually about the size of a microwave, these machines “print” three-dimensional objects by melting plastic and depositing the material layer by tiny layer based on a three-dimensional computer-generated design of a necklace, say, or a fork. More advanced — and expensive — printers can use materials such as metal and chocolate.

For those who are less tech-savvy, there are new smartphone applications that streamline the process of crafting or altering a design. Online markets have also popped up in which shoppers can customize and order 3-D-printed clothing, toys, gadget accessories and other products.

Industry experts say 3-D printing could revolutionize traditional manufacturing, much as the Internet upended the music industry, and fundamentally alter how consumers shop and how much they pay. Some tech companies are already foreseeing a day when every home contains a 3-D printer churning out custom furniture and clothes, or a Kinko’s-esque store in every neighborhood where items can be manufactured on demand via printers.

It’s also raised concerns among law enforcement professionals, who worry that criminals will be able to print untraceable guns and other weapons at home.

“The billion-dollar question is, how big will this become and when?” said Terry Wohlers, president of consulting firm Wohlers Associates, which tracks the industry. “You see companies already making fashion garments and jewelry through printing. And we have seen demonstrations of 3-D printing food and living tissue.”

Wohlers said that by 2021, the U.S. market is estimated to hit $10.8 billion, up from $2.2 billion last year and $$1.18 billion in 2008. The industry has been growing, on average, more than 25 percent a year for the past decade. The consumer side, which is in its nascent stages, is especially ripe for growth, Wohlers said.

‘EASIER TO WORK WITH’

Tech companies are already salivating at the opportunities.

In June, 3-D veteran Stratasys Ltd., which for decades has made ultra-pricey printers for companies such as Boeing Co. and General Motors Co., announced plans to buy MakerBot, which specializes in affordable desktop printers. Rival 3D Systems Inc. launched two consumer-oriented models this year, the Cube ($1,299) and the CubeX ($2,499 and up).

Small-business owners have already taken to the printers.

John Hariot of Los Angeles, for one, is using a printer bought from Deezmaker to create prototypes, such as knobs for drawers, for his new cabinet-making company. He said the 3-D printer is a much cheaper option compared with the pricey rapid-prototyping machines he once had to use.

“It’s much easier to work with, and there’s less waste,” he said.

For consumers who aren’t tinkerers or designers, industry experts say, a potentially bigger market could lie in on-demand services. Think of it as Amazon.com for custom orders, only with no warehouses required because a purse or belt is only made after it’s ordered.

Shoppers can already go on sites such as Shapeways or Cubify, run by 3D Systems, and either find a designer for a custom design or tweak an available product.

More than 10,000 shops have been set up by designers on Shapeways, which manufactures and ships a product after an order comes in, said company spokeswoman Elisa Richardson. Bestselling items include iPhone accessories, jewelry, home decor and wedding cake toppers — grooms and brides-to-be send in photos of themselves and receive toppers with their faces printed on them.

Kimberly Orvitz, a fashion designer who recently launched a 3-D printed jewelry line, said the technology saves money: There’s no requirement to order products in bulk from a factory and no storage costs. Shoppers can also “customize by selecting colors and materials,” she said.

GUNS AND BRAKES

But the technology has not been without controversy.

Cody Wilson, the owner of a gun-manufacturing firm in Texas, made headlines after he successfully fired a 3-D-printed gun of his own design earlier this year (he also uses the technology to make firearm magazines and lower receivers).

For now, such guns may pose more of a danger to the maker. Australian police who tried making Wilson’s design reported the plastic gun exploded after firing. Still, a recently leaked Department of Homeland Security bulletin said such firearms pose public safety risks.

Industry experts say there is more danger in consumers making ordinary products that are defective.

“The gun thing has been way overhyped because if you really want to make a gun, there are better and cheaper ways to do it,” Wohlers said. “But just think about people printing a brake part for their car, and it breaks going down the highway and people are injured or worse.”

For now, the relatively untapped market has allowed not just big corporations but also entrepreneurs to jump in.

Porqueras, the owner of the Pasadena store, was a Hollywood camera technician before becoming fascinated with 3-D printing.

Always a tinkerer, he created his own ideal 3-D printer, started a campaign on the fundraising site Kickstarter, and raised $167,000 — enough to quit his job and start selling his machine full time. He recently launched another campaign to raise funds for the Bukito, his portable 3-D printer priced at $650.

“It just blew my mind what these printers can do,” Porqueras said. “Who knows what the future will hold?”

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.