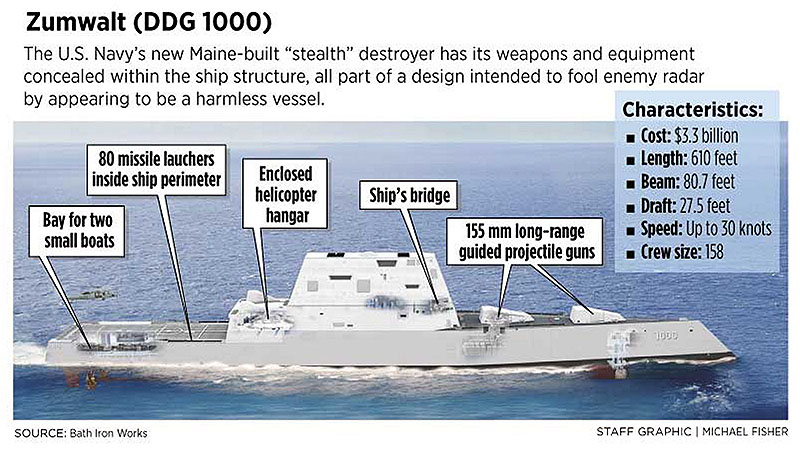

BATH — Sometime next year, the USS Zumwalt will begin testing the Tomahawk missiles, GPS-guided munitions and “total ship” computing systems that will make the $3.3 billion vessel the most advanced destroyer in Navy history.

But first come the cables – 2.3 million feet of them snaking above, below and alongside every corridor of what is essentially a 600-foot-long floating computer.

“Now you have an all-electric ship,” Todd Estes, manager of the DDG-1000 program at Bath Iron Works, said last week.

The 5,000 to 6,000 people who gathered in the BIW “yard” last month for the christening of the USS Zumwalt – the first of three Zumwalt-class “stealth” destroyers to be built at BIW – saw a ship with an exterior that looked largely complete. Inside, however, the Zumwalt was still in full construction mode as an estimated 600 BIW laborers and contractors worked.

But even amid the endless bundles of cables, protective tarps and the organized disorganization of a construction site, it was evident that the Zumwalt’s futuristic-looking exterior isn’t the only way this new generation of destroyer is different from its predecessors.

“Completely different,” Cmdr. David Hart, the Navy’s Zumwalt point person at BIW, said while helping lead a Press Herald reporter through the labyrinthine ship corridors. From the ship’s propulsion plant to the crew cabins, Hart said, the Zumwalt’s design is dramatically different than that of the smaller, Arleigh Burke-class destroyers also under construction at BIW.

“This is a complete revolution,” Hart said.

That revolution begins in the ship’s power plant, which features the largest electrical propulsion motors ever used in a combat ship, according to the Navy.

Bundles of electrical cables as thick as the PVC piping often used in household plumbing run throughout the power plant room to two Rolls-Royce gas-powered turbines and two smaller “advanced induction motors” that will generate enough juice to power everything in the ship – including propulsion – with power to spare for electricity-driven weapons systems still under development.

The Zumwalt is expected to have a top speed of 30 knots, roughly equivalent to the Arleigh Burke destroyer, despite being nearly twice the mass. The Zumwalt’s power system uses 4,160 volts – compared with the 110 volts in a household outlet – and requires hundreds of electricians trained to work in high-voltage systems.

Upstairs in the fully enclosed superstructure, the stations in the ship’s “mission center” and the wall of flat-screen TVs providing a 360-degree view of the outside were largely covered up to protect them from the infrastructure work. Once operational, the center will allow a handful of people to monitor and control every aspect of the ship’s operation.

The Zumwalt is designed to operate with a crew of 158, a figure that includes the personnel who will fly and maintain two MH60R helicopters. Arleigh Burke destroyers, by comparison, have nearly twice as many crew members.

Winding their way through the ship’s interior, Estes and Hart pointed out berthing areas or staterooms – currently used as office or storage space for construction crews – that will house just four enlisted personnel rather than the much-larger bunk rooms found on many Navy ships. Each four-person room also will have its own toilet, or head, and shower stall. A BIW representative suggested that those enhanced creature comforts for crew members might please the ship’s namesake, the late Adm. Elmo R. “Bud” Zumwalt Jr., who focused heavily on improving conditions for sailors when he was chief of naval operations.

But it is the Zumwalt’s “stealth” design that makes it unique among American destroyers.

On the day of the tour, the Zumwalt’s two 155 mm guns towered above the deck. But when not in use, the massive artillery pieces will lower into sloping, lower-profile enclosures on the deck that reduce the ship’s radar profile.

Back at the stern of the ship, work was still underway on the “personnel safety barriers” that will rise along the sides of the helicopter landing pad to prevent aviation crew members from falling overboard. Like the deck guns, the safety barriers will fold back down into the landing pad when not in use. A landing-assistance system will help the helicopters safely land on the flight deck during heavy seas, while an automated system will move the helicopters into, out of and around the basketball court-sized helicopter hangar located behind the superstructure.

A deck below the landing pad, meanwhile, workers were completing work on a fully enclosed “boat bay” that will house two rigid-hull inflatable boats each measuring roughly 36 feet in length. Used to ferry Navy SEALs and other special-operations forces to and from shore, the boats will launch through two enormous doors located on the ship’s stern.

With its clean lines above the waterline and angular “tumblehome” hull designed to reduce the ship’s detectability, the Zumwalt is often described as having the radar signature of a smaller fishing vessel rather than a 610-foot-long steel destroyer.

“You are trying to be as small a blip on the radar as possible,” Estes said.

All of this technology, as well as the years of research and development that went into the ship’s design, is a big reason why the Zumwalt has cost the Navy about $3.3 billion to build, which is more than twice the price of the latest generation of an Arleigh Burke destroyer.

Navy and BIW officials have said they expect the second and third Zumwalt-class destroyers to cost less than the initial ship. But the enormous price has drawn attention. The Navy originally planned to build more than 30 of the destroyers, but eventually whittled the list down to just three ships in response to budget constraints and the Navy’s anticipated needs in a changing global military environment.

The cost and the ship’s destructive purpose prompted more than 100 people to gather outside BIW’s gates during last month’s christening to protest federal spending on such defense programs.

Kevin Miller can be contacted at 317-6256 or at:

kmiller@pressherald.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.