SKOWHEGAN — The Sappi Fine Paper Co. Somerset mill in Skowhegan is now running on natural gas instead of oil, a move the company hopes will shave 30 percent from energy costs and reduce air emissions and other harmful environmental impacts.

Summit Natural Gas of Maine completed the final installation of equipment to allow the Somerset mill to run at full capacity using natural gas, according to Mark Hittie, director of marketing and communications at Sappi North America offices in Boston.

“The Somerset mill is now fully connected,” Hittie said. “We had a (routine shutdown for state-ordered maintenance) in October to complete the final stage of our natural gas conversion project, converting the lime kiln. We are now fully operational on natural gas.”

Hittie said the biggest impact of switching to natural gas is in the mill’s lime kiln, where gas has replaced the equivalent of 80,000 to 100,000 barrels of No. 6 fuel oil used per year. Converting to natural gas will also reduce oil use in the mill’s power boiler and decrease the ash load on environmental equipment.

Summit, which went on line with natural gas at the Madison Paper Co. mill after a six-month delay in April, began installing pipe to Sappi about a year ago.

Converting the mill power plants to natural gas is considered a step toward reducing costs to an industry staggered by economic forces and a declining demand for paper.

In the last decade, higher energy costs and foreign competition have resulted in mill closures around the state. They have also caused dramatic drops in property tax valuations recently in mill communities such as Madison and Skowhegan. Switching to natural gas can help offset those rising costs, Summit executives said.

“The opportunity to utilize natural gas is essential to maintain the competitive cost position of our Somerset mill and is another example of our investment in Maine,” Mark Gardner, president and chief executive officer of Sappi North America, said in a news release.

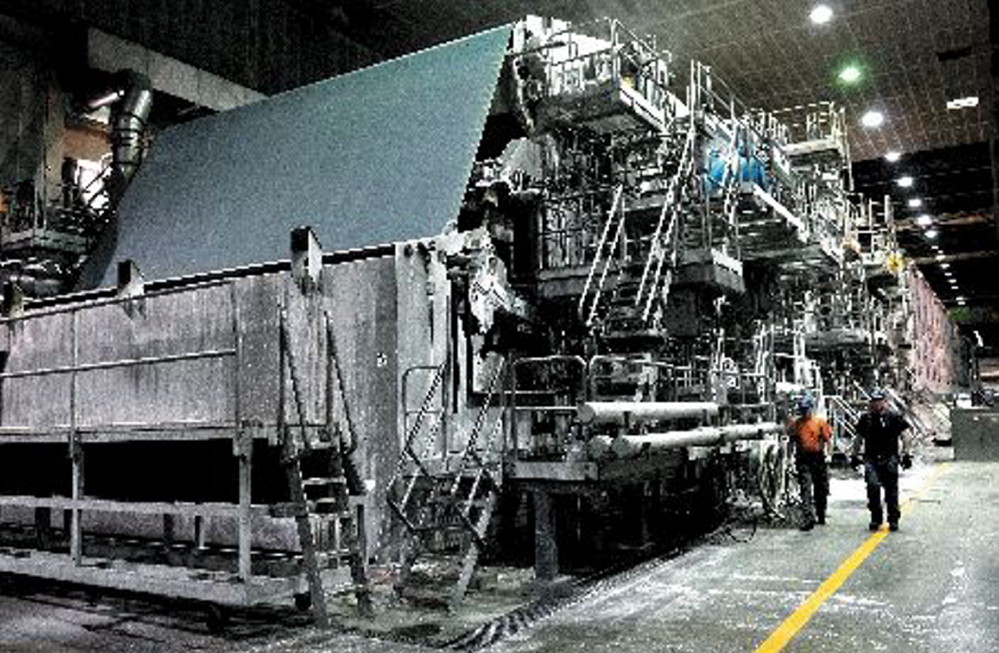

Sappi’s mill in Skowhegan is the seventh-largest coated paper mill in the world, producing more than 2,200 tons of paper per day, according to Summit. The mill also employs more than 700 Maine workers.

Sappi is among a handful of large businesses that made the $350 million gas pipeline possible in the Kennebec Valley. Summit built a far-reaching network, stretching from Pittston to Madison, while its competitor, Maine Natural Gas, focused more on the Augusta area.

Inland Hospital in Waterville and Redington-Fairview General Hospital in Skowhegan last year joined Sappi, UPM Madison and Huhtamaki Packaging in Fairfield and Waterville as prime potential natural gas customers. Summit was also selected by the city of Augusta to provide natural gas service to city schools and other city-owned property, as well as some state government property in Augusta.

Skowhegan Town Manager Christine Almand said work installing the gas pipelines to the mill began in 2013 and the completion of the project is good news for the town and the region as a whole.

“Sappi has made a positive choice to invest in an energy resource that will reduce their costs and increase their profitability,” Almand said. “It is encouraging anytime you see a company invest in their future the way they have.”

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.