YARMOUTH — The space is just a warehouse with boxes of down comforters. There’s no need for intense, always-on lighting. But until this month, the storage area at the Cuddledown factory here was lit with 76 fluorescent light tubes, each rated at 95 watts.

The 8-foot-long fluorescent tube is a familiar, overhead lighting fixture in many Maine businesses. It was state-of-the-art technology in the early 1980s, but today it’s an energy hog.

The 76 tubes here are being replaced with just 10 LED lamps that give off a cleaner light, and are expected to save nearly 20 percent of the company’s $70,000 annual electricity bill. The LED lamps use one-seventh the electricity of their predecessors. In addition, motion sensors will turn off the lamps if nobody walks through the warehouse for 15 minutes.

“The lights used to be on all day,” said Mark Nelson, the company’s vice president of finance.

Cuddledown is one of thousands of Maine companies about to be zapped by electric rate shocks this winter. The limited supply and high cost of natural gas in New England on the coldest days is translating into spiking prices for gas-generated electricity. Last month, officials warned that rates for the state-sponsored standard offer service on which many midsized businesses rely will soar from 6 cents per kilowatt hour to as much as 15 cents in January.

The rate hike covers only the energy supply portion of the bill, not the distribution service. But state energy officials estimate that a typical midsized customer could see energy charges increase from $870 in September to more than $2,000 in January.

This estimate doesn’t involve home customers or small businesses. They won’t see standard offer rate changes until March, when they too should expect prices to rise.

But beyond complaining, or just waiting for new natural gas pipelines to be built, Cuddledown is taking steps to cut its power use.

The warehouse work is part of a $39,000 lighting retrofit that involves 623 new fixtures, downlights and lamps at the factory and corporate offices. Aided by a $14,741 grant from Efficiency Maine, the investment is expected to pay for itself within three years. After that, Cuddledown will save about $13,000 a year on what’s now a $70,000 a year electric bill.

The lighting upgrades at Cuddledown are a prime example of what other companies can do to blunt the impact of rising electric rates, according to Michael Stoddard, Efficiency Maine’s executive director. A study done for the agency found that roughly one-third of the potential energy savings for businesses can be realized through lighting change-outs. The other two leading improvement areas – ventilation and refrigeration – each account for less than one-quarter of the total potential.

“The vast majority of the projects we do with business is in lighting,” Stoddard said. “It just seems like that opportunity exists throughout the Maine economy.”

Over the past four years, roughly 2,000 businesses a year have taken advantage of Efficiency Maine rebate programs, which offer more than 80 different lighting incentives. The agency budgets $9 million for the programs. The money comes from a tiny surcharge on electric bills. The average company saves $8,413 a year, records show.

That level of participation is good, but it indicates that several thousand Maine companies have yet to undertake extensive lighting upgrades. Despite generous subsidies, efficiency upgrades require upfront, private investment. Many business owners simply can’t afford them.

“Most of these business owners look up at the ceiling and see the lights are working,” he said. “They have hundreds of other decisions to make.”

The most-recent figures, however, show that interest is growing. More than 1,200 projects have been logged with Efficiency Maine since July 1, the start of the agency’s fiscal year.

“You’d think that once the word gets out, it will catch like wildfire,” Nelson said of the programs, while giving a tour of the Cuddledown facility.

Nelson first began reviewing the company’s electric demands while looking into power use for the heat pumps that warm much of the complex. But an energy audit showed that obsolete lighting offered the biggest savings, estimated at nearly 133,000 kwh a year. (For comparison, a typical Maine house uses 6,600 kwh annually.)

Nelson also plans other changes to trim Cuddledown’s energy bill. He expects the complex to hook up next year to natural gas, which is being installed now in Yarmouth. That will be used to fire a boiler now fueled with oil.

Nelson also is exploring the option of dumping the standard offer and using a broker to find the best rates for power from a competitive energy provider.

Cuddledown had made initial upgrades when it moved into part of the complex in 2011. It trashed the old fluorescent tubes in the production area and installed what was then a more-efficient fluorescent option. The newer tubes do a fine job illuminating the area, where filling machines pump down into the comforter shells and workers sew them up.

“These are high-end comforters, so we want to see what we’re doing,” Nelson said.

But the pace of change in lighting technology, and the drop in retail prices, has been unexpected and rapid. Four years later, fluorescent tubes are old-school.

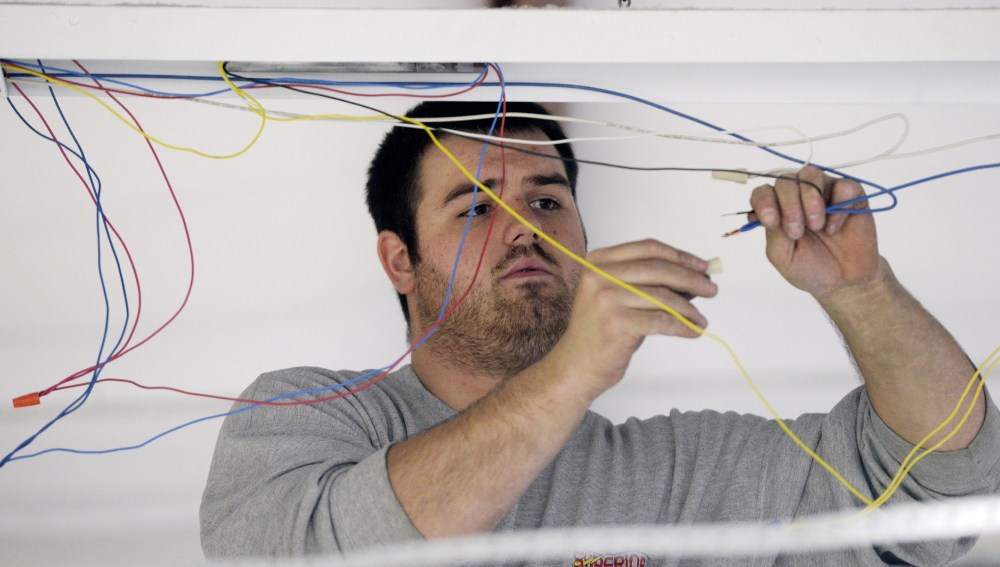

“The LED technology is now so affordable, especially with the rebates,” said Fred Rheaume, owner of Superior General & Electrical in Limington.

Rheaume and his crew have completed much of the project here and were installing the new LED lamps last week in the warehouse. LEDs have an added bonus for businesses, Rheaume said. They can last for 20 years, so the cost of maintaining and changing burned-out lights is greatly reduced.

For this installation, Rheaume’s crew was not only installing motion sensors, but wiring different sections of the 40,000-square-foot warehouse onto separate lighting switches. The warehouse lights used to be controlled at one panel, so everything was either on or off.

The use of motion detectors and zoned lighting is an additional step that can yield great savings for many companies, according to Stoddard.

“Even after good lights are put in, they can make better use of lighting controls,” he said. “A lot more of that could still be done throughout the state.”

This story was updated at 8:45 a.m. on Monday Nov. 24 in order to correct the name of Fred Rheaume, the owner of Superior General & Electrical in Limington. A previous version had misidentified his first name as Steve.

Copy the Story LinkSend questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.