Maine is trailing the rest of New England in developing advanced manufacturing jobs, which require a higher set of skills and also pay better than traditional manufacturing, a new report says.

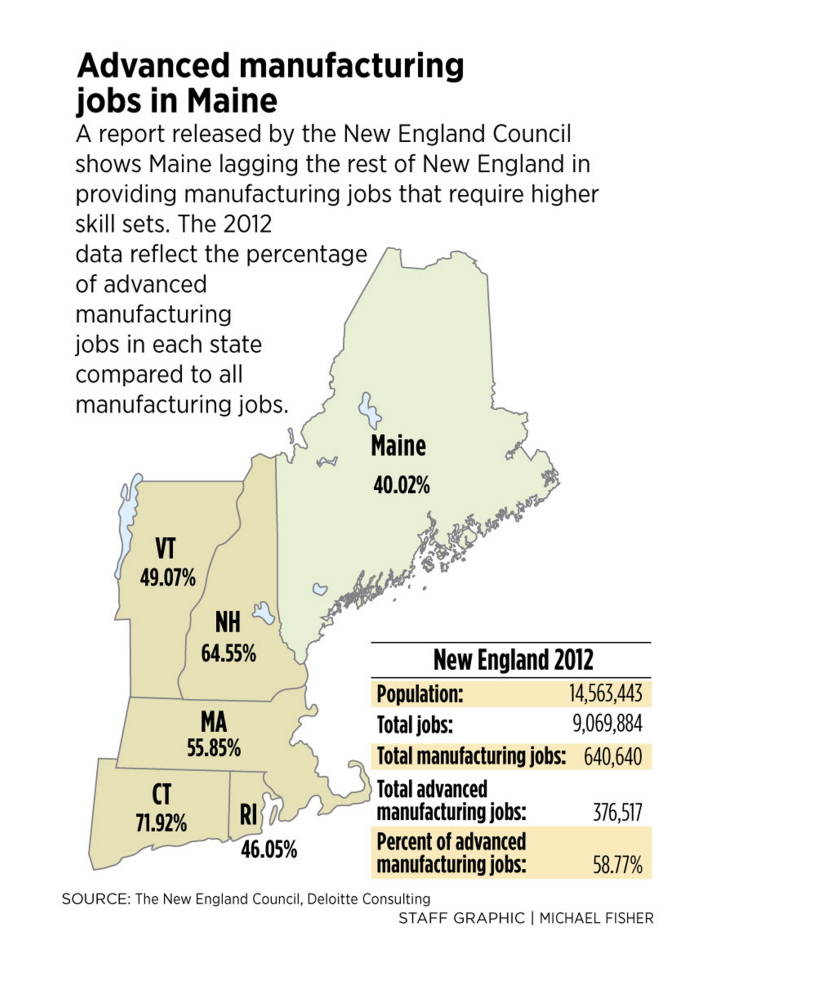

The report, prepared by the New England Council and Deloitte Consulting, says that 40 percent of the manufacturing jobs in Maine could be described as “advanced” in 2012. Every other state in the region had a higher percentage of its manufacturing base consisting of advanced manufacturing jobs, ranging from 48 percent in Rhode Island to nearly 72 percent in Connecticut. The New England average is 58.7 percent.

The New England Council is a regional lobbying group and Deloitte is a consulting firm.

Advanced manufacturing involves new designs and materials, high-tech machinery, such as 3-D printers, and the jobs require well-developed skills to analyze data and use the new machinery. Industries that lead the way in advanced manufacturing include aerospace, defense, biotechnology, semi-conductor manufacturing and precision machining.

Maine’s manufacturing base has eroded over the past 20 years, primarily because of the continued contraction of the paper industry in the state. Manufacturing jobs are highly prized because they traditionally pay well and provide good benefits.

According to the report, Maine had more than 55,000 manufacturing jobs as of 2012, but only about 22,000 were considered to be in advanced manufacturing. Most of those jobs are clustered in southern Maine. For instance, the report said that 47 percent of the manufacturing jobs in Cumberland County were in advanced manufacturing, while in Piscataquis County, only 2 percent were.

The low number of advanced manufacturing jobs in Maine – at least compared to other New England states – stands apart from wider business concerns about the availability of highly skilled workers. Many government officials and business executives say that they can’t find enough job-seekers with the skills needed to fill open jobs in other industries such as biotech and IT. Instead, the report suggests that Maine businesses aren’t creating many of the high-skilled advanced manufacturing jobs as neighboring states.

The report said New England has an edge over other regions in developing advanced manufacturing, although that position of strength is eroding.

New England’s cost of doing business remains higher than most other areas of the country, the report found, and there’s a shortage of qualified workers, particularly with baby boomers nearing retirement. But, the report said, advanced manufacturing also thrives where there are strong networks among businesses, so they can share advances in designs and production methods, which contributes to higher productivity.

New England already has those networks, the report said, some of which date back to the dawn of the Industrial Age.

John Belding, director of the University of Maine’s Advanced Manufacturing Center, said that’s a strength in Maine as well, where students who take advantage of learning advanced manufacturing techniques often end up working for Maine companies, such as General Electric, which builds high-tech turbines in Bangor; Pratt & Whitney’s jet engine plant in Berwick; and the Bath Iron Works shipyard in Bath.

“My phone come January starts ringing off the hook,” he said, with companies looking for students who are about to graduate with an engineering degree and a background in advanced manufacturing techniques. But, he said, although many of the university’s graduates leave with engineering degrees, not many are taking advantage of his center to learn about advancement manufacturing techniques.

He said the students’ background at the university helps foster collaboration, even if they are working for different companies after they graduate. That gives Maine a small, but growing, cluster of advanced manufacturing workers, he said.

Belding said most advanced engineering jobs require data management skills because high-tech equipment often provides a lot of feedback for users. Being able to interpret what the machine is communicating is essential to operating them properly, he said.

For advanced manufacturing to grow in New England, the report said, education institutions need to create pathways for students to get the skills the new manufacturing jobs require. Small manufacturers should also be better supported, the report said, and government should establish policies that aid advanced manufacturing by reducing the cost of doing business, streamlining the regulatory process and supporting growth in the sector.

Belding said New England has been unsuccessful in landing much federal aid to support advanced manufacturing, although he noted that a bill in Congress would set up “manufacturing universities,” which would receive $5 million a year for four years to improve their engineering programs by emphasizing manufacturing and steering more students into manufacturing internships. If the University of Maine were able to secure that designation, he said, it would significantly help in trying to further advanced manufacturing in the state.

There are some small efforts to help toward that goal. For instance, Pratt & Whitney is working with York County Community College to attract more employees to its plant in Berwick, said Leo Dionne, the company’s transition manager.

Dionne said the six-week program is for students with good mechanical skills who may not have a background in machining. He also said that the company is trying to burnish manufacturing’s image in high schools.

Recently, Dionne said, a high school student told him that his father told him that manufacturing jobs were found in a dirty, noisy factory. So Dionne arranged a tour for the boy and his father of the Pratt & Whitney’s plant in Berwick, where the student was impressed by the high-tech machinery and neat, quiet workplace.

“By the end of the tour, the father was wondering if there might be a job for him here,” Dionne said.

Edward D. Murphy can be contacted at 791-6465 or at:

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.