Zootility Tools has big plans to produce and sell a steel menagerie of animal-shaped pocket tools in Portland.

The Massachusetts-based startup has opened a manufacturing, packaging and distribution facility in East Bayside and already is producing thousands of ultra-thin tools per week with names like PocketMonkey, Headgehog and Beer & Friends. It also plans to open a retail store at the 170 Anderson St. location.

So far, the company has seven employees working at its Portland facility.

Zootility’s first product line, the PocketMonkey, has sold more than 250,000 units, according to company spokesman Chris Bent. Designed to fit into a conventional wallet, the tool can be used as a ruler, bottle opener, vegetable peeler, screw driver, hex wrench and more.

It launched the product in late 2012 with a successful Kickstarter campaign that raised $27,550 from 1,921 backers. The PocketMonkey’s 12 different tools are crammed into a 1 millimeter-thick stainless steel plate the size of a credit card.

HEADGEHOG, BEER & FRIENDS

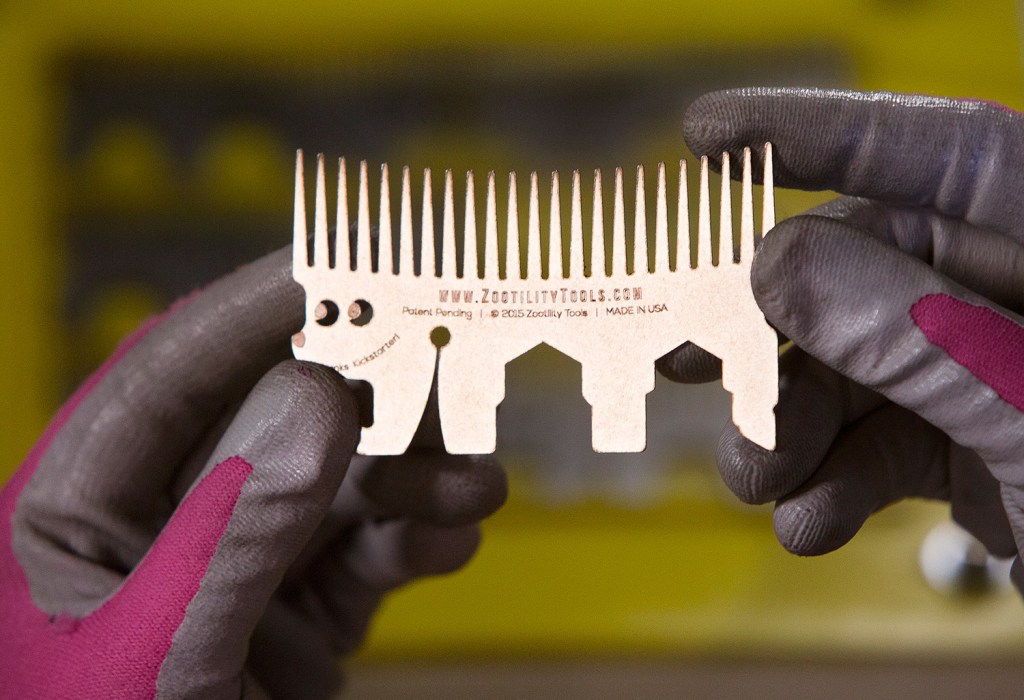

Since then, Zootility has launched two additional product lines, each with its own Kickstarter campaign. The Headgehog, launched in December, is a small steel comb that also serves as a wrench, bottle opener, phone kickstand and chip clip. The campaign raised $11,441, more than double its $4,500 goal.

On Monday, Zootility launched its third Kickstarter campaign for a line of wallet-size bottle openers in various animal shapes called Beer & Friends. Within the first 24 hours, backers had pledged more than $2,800 toward the campaign’s $4,272 goal.

“We’ve found it kind of a good release strategy to do a Kickstarter campaign for every new product,” Bent said.

Zootility also has been selling the PocketMonkey at trade shows, sporting goods stores, outdoor products retailers and online at Amazon.com and on its own website. It comes in both basic and deluxe models, which retail for as little as $10 and $12, respectively.

The company’s products begin as large plates of metal produced by a contract manufacturer in the Midwest. The basic models also are stamped out of a die press at the same facility.

In Portland, Zootility has three machines that cut and etch the deluxe models with industrial lasers. It also has a tumbler for smoothing out the tools’ edges, as well as packaging and shipping facilities.

All of Zootility’s tools are the inventions of company founder Nathan Barr, a Boston-area designer and engineer. The company’s first in-house manufacturing facility was in a 900-square-foot space in Westbrook, which it quickly outgrew. Barr wanted his tools to be made entirely within the U.S., and industrial space in the Portland area is less expensive than in Boston.

Zootility recently acquired a $200,000 fiber-optic laser cutter that has allowed it to increase production and do more of the work in-house. It also has a less-powerful carbon dioxide laser cutter and a laser etching machine.

Steve Trageser, distribution manager at Zootility’s Portland facility, said the computer-controlled lasers can cut 84 tools out of each plate with great precision. The company has been experimenting with automation to load and unload the machines but still does the bulk of that work by hand.

“When we get the thing running full speed, we can do 500 a day,” he said.

New product orders keep rolling in, Trageser said, and the company has been operating in three shifts to keep up with demand.

“We insist on doing everything ourselves,” he said. “We’re still moving more products than we ever thought possible.”

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.