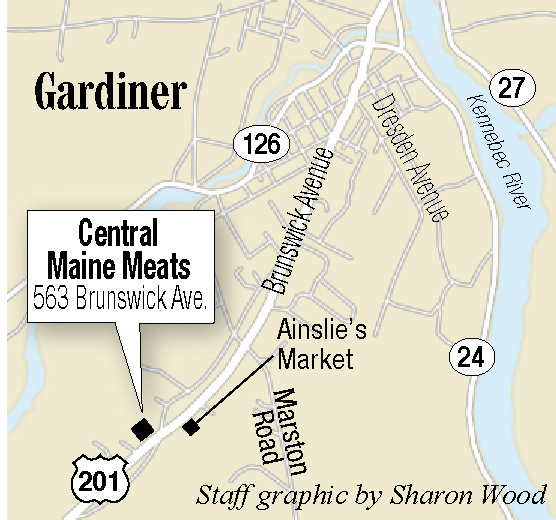

GARDINER — The flash-freezing tunnel that Central Maine Meats uses in its Brunswick Avenue facility is relatively small by industry standards, but it is mighty. It can flash freeze up to 3,300 hamburger patties a day, and that’s the technology that the owners of the Gardiner-based slaughterhouse see as the key to preserving Maine agricultural products for year-round consumption in Maine and anywhere else the food can be shipped.

“Can you imagine sitting in California and ordering up a lobster tail and a steak to be flash-frozen and overnighted?” Bill Lovely, co-owner of Central Maine Meats said Monday.

It’s within the realm of possibility, but it’s not the only opportunity out there.

Central Maine Meats can make up smaller packages, which opens up markets at small, local retailers and co-ops, she said. The company also has the capability to use stock keeping units (SKUs) and bar codes, allowing meat to be traced back to the farm of origin.

The tunnel, manufactured by Matheson Gas, is essentially a large metal box that uses nitrogen dispersed by fans to freeze any item that’s carried through the freezing chamber on the machine’s conveyor belt. Freezing is controlled by the temperature set on the machine, the length of the conveyor belt and the time it takes an item to make its way through the chamber.

The flash-freeze technology preserves freshness by sealing in moisture. The items that are frozen don’t stick together and when they thaw, they don’t suffer from the cell breakdown that traditional freezing can cause.

Plans have been in the works for a large-scale flash-freeze facility at the Libby Hill Business Park since before the middle of last year, when the Gardiner Planning Board approved the company’s proposal.

Davis anticipates having five or six tunnels, ranging in size from 18-20 feet long to 40 feet long.

In the meantime, Central Maine Meats employees are learning the technology and using the 12-foot tunnel at the Brunswick Avenue facility to fill orders and preserve meat.

“The question is, can we scale the food opportunity to such a scale that agricultural producers come to our facility?” Davis said.

Jessica Lowell can be contacted at 621-5632 or at:

jlowell@centralmaine.com

Twitter: JLowellKJ

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.