A Guilford manufacturer that began more than 100 years ago making mint-flavored toothpicks is now producing a million COVID-19 testing swabs per week.

With demand for the swabs climbing, however, it finds itself in need of more workers.

Family-owned Puritan Medical Products Co., one of the top two makers of testing swabs in the world, according to Kaiser Health News, recently added 31 temporary workers to its team of 300 on the production floor and is looking to add more.

“The demand has gone through the roof,” said Scott Wellman, chief financial officer of Hardwood Products Co., parent company of Puritan. “We were able to fast-track hire 31 people, but we’re looking to hire another 10 to 15, mainly because we need enough people to run all the machines.”

The factory now runs two 10-hour shifts per day, six days per week. Wellman said employees have volunteered to work weekends and overtime to meet demand.

“These people are tired, but they’re doing such a great job,” said Timothy Templet, co-owner of and executive vice president of global sales at Puritan.

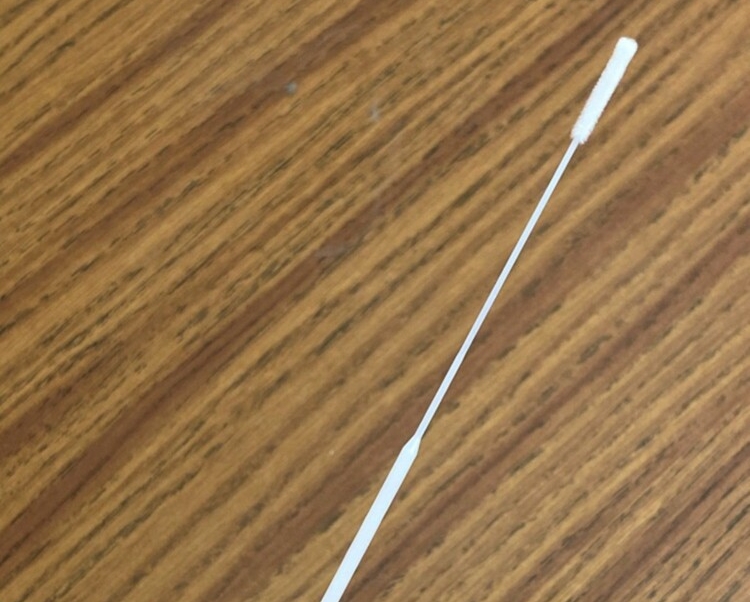

The swab used for COVID-19 testing has a plastic handle with synthetic materials attached at the tip. The handle of the swab must be long enough to reach past the nasal cavity into the upper part of the throat to perform the test, according to Templet.

Though demand for the swabs has risen, Puritan has had no trouble acquiring the raw materials needed to make them. No wood is used in their manufacture, according to Kaiser Health News, and other material specifications must be met to insure the swabs are effective in testing for COVID-19.

Before the coronavirus pandemic, Puritan sold its products through distribution networks in the United States, Canada, Mexico, Central America, South America and elsewhere across the globe.

“We don’t sell direct to hospitals,” Wellman said. “We sell to major medical distributors, like Cardinal Health, McKesson Medical-Surgical” and others.

After provisions of the Defense Production Act of 1950 were implemented in response to the pandemic, however, Wellman said Puritan has been providing swabs directly to the federal government, including the Department of Health and Human Services and other agencies, in addition to selling to its regular customers.

Wellman was unable to confirm whether the company’s tests were being sold to hospitals and drive-thru testing sites in Maine.

With an increased number of employees on the production floor, Templet said the company is taking extra precautions to ensure the health and safety of its workers.

“We take their temperatures every day,” Templet said. “The place is incredibly clean. Workers producing the tests wear masks, gloves and eye protection. We stagger the lunches and breaks so there aren’t too many people in the break room at once. We’re doing the best we can.”

Together, Hardwood and Puritan employ more than 500 people with more than 300 producing swabs in one building, with the rest of the employees working in other buildings.

Wellman said employees on the production floor and in the general office spaces are required to wear face masks per recommendations from the U.S. Centers for Disease Control & Prevention.

There have been no confirmed cases of coronavirus in any workers at Puritan or Hardwood. As of Sunday afternoon, Piscataquis County was the only county in Maine with no confirmed positive coronavirus cases.

Statewide, cases had risen to 633, with 19 deaths, as of Sunday.

Along with Puritan, Kaiser Health News identified the Italian company Copan Diagnostics Inc. as the other major producer of COVID-19 testing swabs, producing 720,000 per day.

Puritan Medical Products started making swabs in 1965 and was certified by the U.S. Food and Drug Administration in 1975. It now produces 65 types of swabs and 1,200 single-use items, according to company data on its website, with health care, diagnostic, forensic, food safety, drug manufacturing and other applications.

Puritan operates alongside its parent company, Hardwood Products Co., which began making toothpicks in 1919 but added to its product line over the years to include tipped applicators, tongue depressors, disposable woodenware for the food and dairy and craft industries, including ice cream sticks, spoons and skewers.

With about $55 million in annual revenue, Hardwood is the biggest employer in Piscataquis County, the least-populated county in the state with just 17,000 residents. Guilford’s population was 1,500 when documented for the 2010 census.

Copy the Story LinkComments are not available on this story.

Send questions/comments to the editors.