DETROIT – Nissan Motor Co. said Thursday it is considering moving some engine production from Japan to the U.S. because of earthquake damage to a Japanese plant, another illustration of how seriously the disaster has upended the global network of auto supplies.

Car factories could face serious shortages of Japanese parts by the middle of next month unless Japan’s auto industry can quickly restart its shuttered production after a devastating earthquake and tsunami on March 11, experts say.

As stockpiles of parts from Japan run low in the coming weeks, some North American plants are bracing for shutdowns. Toyota has warned workers it may idle operations.

“The impact of the supply shortage will begin to be felt more intensely by global automakers by the middle of next month,” Paul Newton, auto analyst with the research firm IHS Automotive, said Thursday.

Supply disruptions in Japan generally are felt by U.S manufacturers three to four weeks later, depending on a company’s stockpiles, Newton said. That’s because of the time it takes to ship parts from across the globe. So shortages caused by Japan’s March 11 disaster could hit the U.S. by mid-April.

Newton said the Japan disasters could result in a 30 percent drop in global automotive production. It’s still unclear how much money will be lost due to the plant closures, he said.

He predicted there will be rolling shutdowns of plants, starting as soon as next week, as car companies realize they are about to run short of parts. Plants could deal with short-term shutdowns for the next few months, Newton said.

“It is quite a sharp drop as the supply chain issues filter through,” he said.

Toyota Motor Corp. said late Wednesday that it expects to halt production at some of its North American factories, but doesn’t know when or for how long.

The impact should be limited, Toyota said, because most parts used in its North American factories come from a network of 500 suppliers based in the region. It continues to get parts shipments from Japan that were en route before the magnitude-9.0 quake struck that nation.

The company has already suspended overtime and Saturday shifts in North America, where it has 13 plants that build 70 percent of the cars and trucks it sells in the U.S.

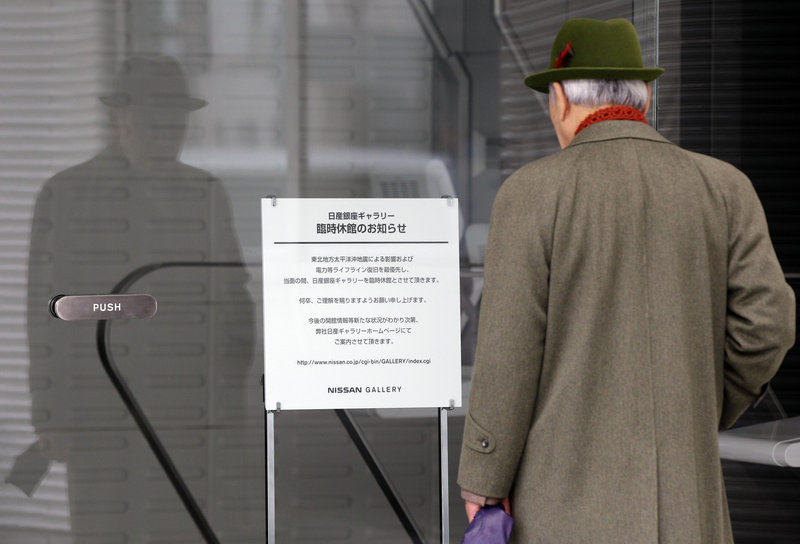

Nissan said Thursday that its U.S. plants will operate at full production through April 1, and may even pick up some business due to damage at the Iwaki engine plant in Japan. Nissan is studying whether to have its Dechard, Tenn., engine plant supply six-cylinder engines to Japan.

Honda Motor Co., Mazda Motor Co. and Mitsubishi Motor Corp. said Thursday that North American production is continuing normally.

In February, North American production reached 1.06 million vehicles, 15 percent higher than the same month a year earlier. But near-term production is beginning to be hurt by parts shortages from Japan, said Jeff Schuster, executive director of global forecasting at J.D. Power and Associates. In addition to scaled-back production at Toyota and Subaru, GM has idled manufacturing at its Shreveport, La., pickup plant.

“With the uncertainty remaining high about the full extent of the parts supply situation, North American production could be impacted in the weeks to come,” Schuster said.

In Japan, Toyota plans to resume production of the Prius and two Lexus hybrids — the HS 250h and CT 200h — on March 28. The Prius is made at the Tsutsumi factory in western Japan, and the Lexus models are produced in the southern island of Kyushu, areas outside the epicenter of the disaster.

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.