To many businesses in Maine, three-dimensional printing is more than just a gimmick or a fad.

A growing number of companies are taking advantage of recent improvements and cost reductions in 3D-printing technology to design new products more quickly and inexpensively, business owners and engineers say.

While many recent headlines about the technology discuss the possible dangers of 3D-printed weapons, experts in Maine say 3D printing can be used to make virtually anything and is particularly useful for prototypes, customized products and complex geometric shapes.

Advocates for 3D printing in the state say not enough companies and consumers are aware of what the technology can do, and why it is so important to the future of manufacturing.

University of Southern Maine staff member Gregory Cavanaugh and 3D-printing consultant Sarah Boisvert have teamed up to organize a conference scheduled for Friday at USM in Portland.

The inaugural Digital Fabrication & 3D Technologies Conference & Expo will showcase the latest in 3D printing, computer-aided design, 3D scanning, laser-based manufacturing and other cutting-edge digital design and fabrication technologies, they said. The conference is designed to offer something to both companies and educators.

“A lot of manufacturing has left this country, and 3D printing is a way to bring some of it back,” said Cavanaugh, assistant director of experiential education at USM’s College of Science, Technology and Health.

Several companies in Maine already are using 3D printing to make a diverse array of products ranging from robotics to jewelry, said Boisvert, owner of 3DMicroFactory, a digital design and fabrication firm based in Rockport.

“My guess is that a small number of Maine companies have made the leap – maybe 5 to 15 percent, but more are interested in how to get started,” she said. “That is one of the big requests we got from Maine manufacturers and educators about the subjects for the (conference) talks.”

Three-dimensional printing, also called “additive manufacturing,” involves special printers that can construct a solid, three-dimensional object from a digital design.

The term “additive manufacturing” refers to the fact that objects are constructed by adding layer upon layer of the building material, often plastic, rather than by removing or cutting away material.

Printers come in a variety of types. One of the most common uses plastic “extrusion deposition,” in which a plastic filament is fed into a nozzle that heats the plastic to a liquid state, then pipes it out like icing through the tip of a pastry bag.

Meanwhile, the printer head moves left, right, backward and forward over a metal plate, known as the “stage,” slowly building the 3D plastic object one layer at a time.

In some printer models, the nozzle rises slightly after each layer of plastic is laid down, while in other models the stage lowers slightly.

The proliferation of 3D printers has caused some concern among law enforcement that they could be used to create weapons. Earlier this year, a law student in Texas posted directions online for making a 3D-printed handgun. Authorities in Europe, which has stricter gun-control laws than the U.S., have also said they fear the technology will make it easier to obtain a weapon.

Despite the recent introduction of relatively low-priced consumer 3D printers on the market (as low as $300 for a Printrbot Simple), experts said it requires at least a mid-range consumer printer such as a Makerbot Replicator 2 ($2,200) or a Cubify CubeX ($2,500) to reliably produce small commercial products.

Even those printers don’t always work the way they are supposed to, Boisvert said. It’s not unusual for them to get off track and end up producing what looks like a pile of plastic spaghetti.

The more expensive commercial-grade 3D printers are far more precise and reliable, but they cost hundreds of thousands of dollars. Also, higher-end printers can combine multiple colors or materials, while lower-end printers can’t.

The plastic filament isn’t cheap, either, costing as much as $50 for a spool that weighs about 1.5 pounds.

Cavanaugh noted that using a 3D printer to produce, say, a simple plastic cup, would cost many times more than buying one at the store. “Sure, you could do it that way, but it would be a very expensive cup,” he said.

The process is especially useful for producing one-off designs and complex geometric shapes that would be difficult to manufacture any other way, Boisvert and Cavanaugh said.

To mass-produce a product, they said, it is far cheaper and faster to create a mold, set up an assembly line and produce multiple copies. But what if you only need one copy?

For example, Invisalign braces, which are made of clear plastic, are custom 3D-printed to fit each user’s teeth. It would be far more expensive to make them using a traditional manufacturing process, Boisvert said.

Aerospace companies also are interested in 3D printing because they can use it to make porous structures that are strong and light, Cavanaugh said.

“You’re able to achieve geometry that you couldn’t get any other way,” he said.

Steve Franklin, engineering manager at Westbrook-based Lanco Assembly Systems, said his company uses 3D printing to make plastic prototypes of certain parts before sending the designs off to be machined in metal.

Lanco produces robotic assembly-line equipment for the mass-production of automotive parts and other mass-produced items. Every job Lanco does for a customer requires a custom design, which makes 3D printing ideal for prototyping, Franklin said.

“We know if (a part) will work within a matter of hours, rather than within days or weeks,” he said.

Creating designs for a 3D printer also can spur the creative process and result in something new and unusual, said Charles Duvall, owner of Rockland-based Duvall Design.

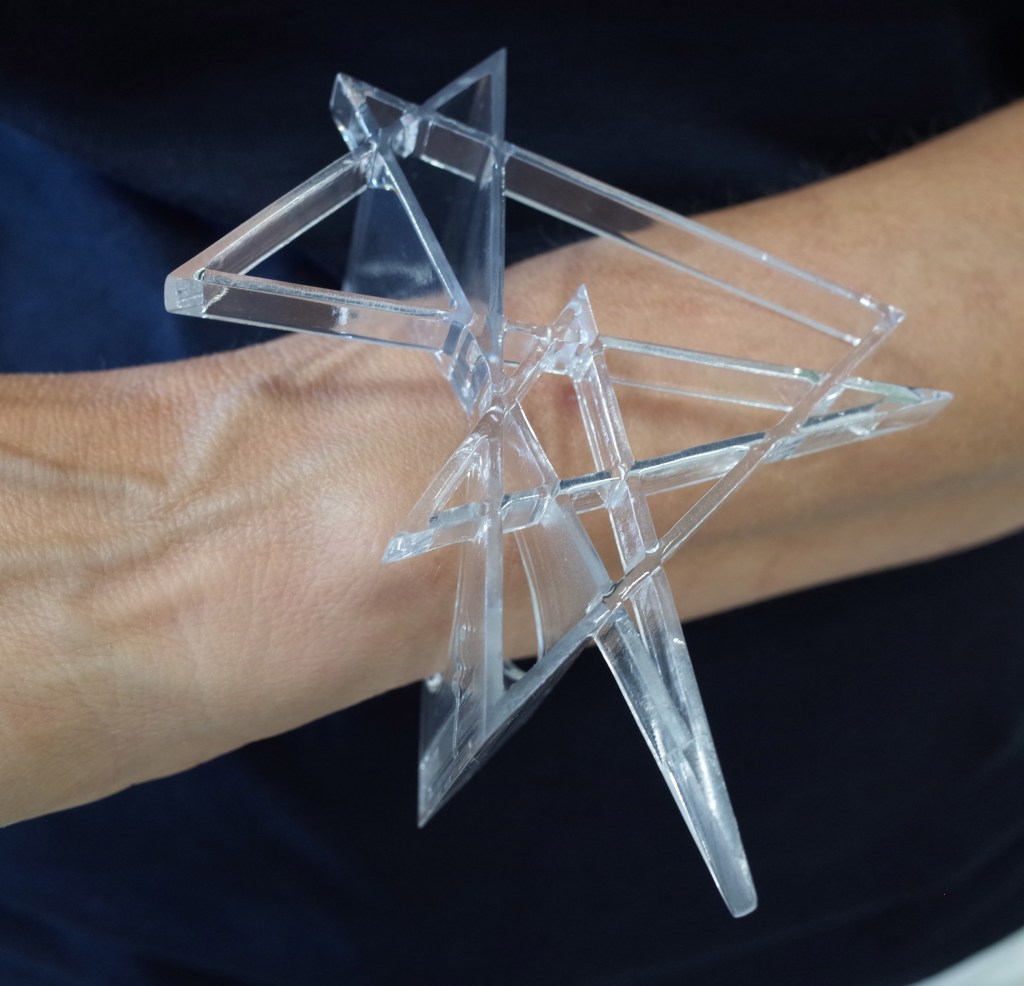

Duvall, a computer-assisted designer with a diverse background, said he is leaving for Europe in November to show off his 3D printed jewelry at fashion shows in London and Paris. He calls his accessories “architectural wearables” because of their complex, multilayered structures.

“It’s sort of a different way of thinking about jewelry, so you end up with a different result,” Duvall said.

For more information about the Digital Fabrication & 3D Technologies Conference & Expo, visit digifabconference.com or call 780-5450.

J. Craig Anderson can be contacted at 791-6390 or:canderson@pressherald.com@jcraiganderson

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.