It’s a quiet evening in February, and I’m sitting in Miyake in the Old Port, getting a crash course in sake from Dan Ford and John Sygowski.

They start me off with a glass of Ippongi Denshin Rin Daiginjo, an aromatic sake with notes of lychee and pear.

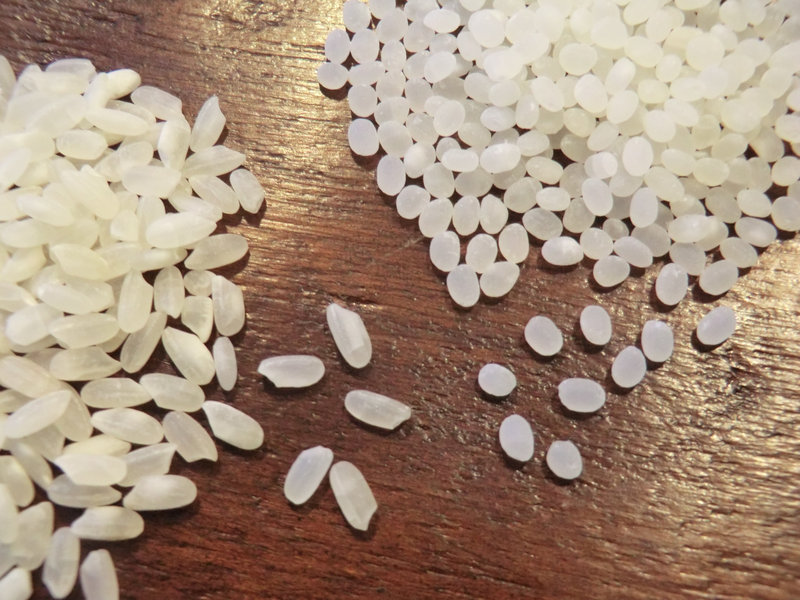

The rice used to make a daiginjo, I learn, has been highly polished. Fifty percent or more of the kernel has been milled away so that there is mostly starch remaining, and that means better flavor.

A glass or two later, I try a namazake, an unpasteurized sake. (Most sake is pasteurized twice.) “A lot of the flavor’s in the front of your mouth,” Dan said. “It’s sort of bright, and then just fades. That’s namazake.”

Ford is impressed by the sake menu at Miyake, noting it’s “the best I’ve seen north of Boston, without a doubt.”

He and his business partner, Sygowski, know what they’re talking about. Ford is an advanced sake professional – a master taster similar to a master sommelier for other types of wine – who studied with John Gauntner, the first non-Japanese certified master taster of sake and president of the sake education council in Tokyo.

Sygowski is a certified sake professional.

Ford and Sygowski plan to open a sake microbrewery this spring, right here in Maine.

The two friends already brew for their personal consumption in the garage at Ford’s home in Kittery Point. That’s where the commercial operation, called Blue Current Brewery, will begin once they have all their local, state and federal permits in hand. They hope to be open for business by April or May, and will eventually move the brewery out of Ford’s house.

According to Gauntner’s website, there are only seven sake breweries in the United States. Most of them are backed by corporations. Once Blue Current is up and running, it will be one of just two sake microbreweries in the country that are not only making their own sake, but also bottling and distributing it for sale. The other one is the Texas Sake Co. in Austin.

There’s another sake microbrewery that’s been seeking investment for a start-up in Asheville, N.C., but Ford says he expects Blue Current to be the first commercial sake microbrewery operating on the East Coast.

A NOD TO MAINE ROOTS

Blue Current’s first sake will be called First Light, in honor of Maine. Ford and Sygowski are hoping Maine restaurants will jump at the chance to serve their customers a local sake.

“We really have a passion for sake,” Sygowski said, “and the more we drink, the more we love it. There’s a lot of sake we taste, and we’re like, we could beat this hands down. We’ve had batches that didn’t come out the way we wanted them to come out, and they’re still better than some of the stuff we’ve been able to buy.”

A sake microbrewery seems like a natural progression for Maine, considering there are already dozens of craft beer brewers in the state, with even more in the works, and distilleries are starting to pop up all over the place too.

Ford said he first got interested in brewing sake in 2010 after he bought a make-your-own kit in Portland. He had spent part of his career working for a bank in Japan and living in Tokyo, which is where he developed an appreciation for the rice wine.

By 2008, Ford was back in the United States working in the financial services industry. When the economic crash came, he lost his job. After months of searching for work with no luck, he decided to create his own job. Brewing sake appealed to him because it seemed like it had a wide-open market in the United States.

Sygowski is retired from law enforcement work in Massachusetts. He and his wife moved to Florida for a while to try selling real estate, but they missed New England and decided to move back here, settling in Hudson, N.H. (They are planning a move to the Portsmouth-Kittery area shortly to be closer to the brewery.)

Sygowski’s brother-in-law was good friends with Ford, and that’s how they met. Ford began teaching Sygowski about the finer points of sake.

“When Dan talked to me about coming on board with him,” Sygowski said, “I was like the majority of the population in the states: ‘Oh that’s that warm stuff that you drink at a Japanese restaurant while they’re cooking the food in front of you.’

“I started reading up on it, and Dan was serving me different types that he had brought back from Japan, and I’m like, ‘This is cold, it’s not warm.’ “

(When sake is served warm, Ford said, it’s usually to improve the taste and hide imperfections.)

Brewing sake is not as easy as brewing beer. Sake is “the hardest thing to brew on the planet,” Ford said. You have to be part microbiologist and have a lot of patience.

IT STARTS WITH WATER, RICE, YEAST

Sake starts with water, rice, yeast and the mold aspergillus oryzae, which is called kojikin. Once the mold is added to and grown on the rice, the mold-rice mixture is known as koji.

A starter batch, or moto, builds up the yeast that will convert the starches in the rice to sugar. Then the primary fermentation, known as moromi, is developed in three stages, doubling in size at each stage.

It can take just a couple of hours to get beer into a fermenter, Ford notes. With sake, it takes two weeks to build the moromi, and then another four weeks to finish making the sake.

“You have to grow mold, and it takes roughly 40 hours to grow the mold,” Ford explained. “And then you have to add very specific water content to the rice, and it has to be steamed for a very particular amount of time, depending on the polish.”

Before it can be bottled, the sake has to be pressed, filtered and pasteurized.

Add in variables from the climate, the type of rice and yeast that were used, and so on, and there are seemingly infinite paths to a good sake. Quality depends a lot on the type of yeast, which is responsible for a lot of the flavor in sake, and the type of rice and how much it was milled.

“Most of the dryness or type of dryness will come from the rice, or the milling,” Sygowski said, “but most of the flavor will come from the yeast. With the koji, you’re going to get a nutty flavor. You’re not going to discern too much of it.”

There are roughly 400 identifiable flavor notes in wine, Ford said, but there are 2,000 identifiable flavors in sake.

To prepare for opening Blue Current Brewery, Ford and Sygowski have been touring other breweries and learning from other sake brewmasters, including Blake Richardson in Minneapolis, owner of moto-i, the first sake brewery restaurant outside of Japan.

“He invited us to come and brew with him and learn the way he’s doing it, Sygowski said, “So we just spent a week in Minneapolis brewing with him and his apprentice. And we’re actually talking about a trip to Japan next year. It’s great to be in an industry where people are OK with sharing their knowledge.”

They’ve also recently visited Ontario Spring Water Sake Co. in Toronto.

Ford and Sygowski have been buying as much of their equipment locally as they can, but a rice mill is much too expensive to buy on their own.

There is just one Japanese rice mill available for commercial hire in the entire country, and it’s in Minnesota. Blue Current Brewery’s rice gets shipped from California to Minnesota, where it is milled and then shipped to Maine.

Blue Current Brewery’s signature sake will be a ginjo, which means 40 percent of the rice grain has been milled away. They are using Akita Komachi rice, a Japanese kojikin and Japanese yeast No. 7, a yeast that was developed 300 years ago by a brewery in Nagano.

After First Light is released, Ford and Sygowski hope to develop some other sakes and perhaps deal in some side products too, such as the kind of distilled sake that’s popular in Korea.

“We’d love to do a draft sake,” Ford said. “That would be kind of cool.”

Staff Writer Meredith Goad can be contacted at 791-6332 or at: mgoad@pressherald.com

Twitter: MeredithGoad

Copy the Story Link

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.