Jobs and energy. In promoting his energy legislation, Gov. Paul LePage has tied Maine’s economic growth to the cost of energy.

“One of the largest inhibitors, if not the biggest obstacle to job creation is Maine’s high energy costs,” he said in introducing his package of energy bills this month.

It’s a strong statement, but according to economists, business brokers and labor department statistics, it’s not accurate.

No business wants high energy bills. That goes double for the state’s existing manufacturers, for whom electricity and heat can be a large part of overall costs.

But the manufacturing sector has been shedding jobs in Maine for decades, shrinking by 28,800 employees between 2000 and 2010, according to the Maine Department of Labor. Most new jobs in recent years have been in service sectors. Looking out to 2018, the department expects 80 percent of jobs to be created in education and health services, professional and business services, and leisure and hospitality.

For these businesses, a deep labor pool and skilled work force are more important than energy prices.

But the LePage administration has ignored these trends by making the link between its package of four, energy-related bills and job growth.

The bills include controversial proposals to shift money away from Efficiency Maine’s conservation programs and offer low-interest loans for high-efficiency electric heating systems.

Another effort would change renewable energy rules to try to attract hydroelectric power from Canada.

MARKET FORCES AFFECT RATES

Gov. LePage frequently laments that Maine’s electric rates are 12th highest in the country. He doesn’t mention that the same U.S. Energy Information Administration figures show Maine has the lowest commercial rates north of Pennsylvania, which benefits from cheaper coal and nuclear power.

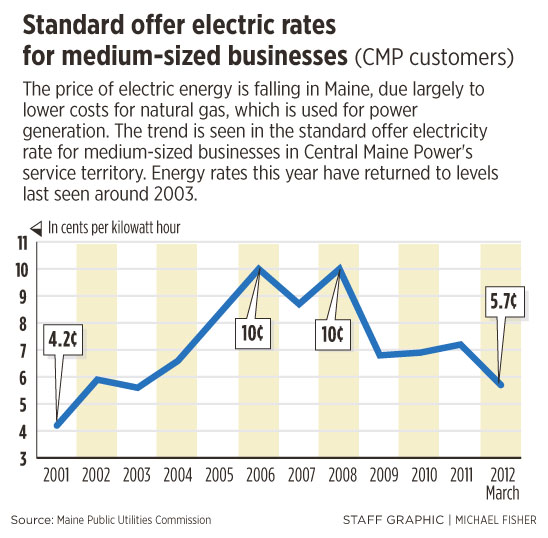

Also left unsaid is that Maine’s standard offer rate for electric energy is falling dramatically this spring. It’s down by more than 12 percent for small commercial customers, and more than 25 percent for industrial customers, compared to a year ago, according to the Maine Public Utilities Commission.

The drop has nothing to do with politics or state policies. Market forces have cut the cost for natural gas, which is used by many power generators in New England. Despite the improvements, New England’s power generation mix can’t compete on price with coal and government-subsidized hydro projects in the South and West.

So for energy-intensive companies looking to expand in the United States, Maine isn’t on the radar screen, according to Peter DelGreco, president and chief executive officer of Maine & Co., a Portland-based consulting firm that helps companies locate and expand here.

“If energy is important to a company, chances are they’re not going to pick New England,” DelGreco said. “Site location consultants would tell their clients, ‘don’t even look at the Northeast.’“

DelGreco said he couldn’t recall the last time a large manufacturer moved here.

MAINE’S CHANGING ECONOMY

On the other hand, Maine & Co. has helped bring fast-growing employers with hundreds of jobs to Maine in recent years. They include Carbonite Inc., an online backup firm; NotifyMD, a medical call center; and Athenahealth, a health care information technology firm. They were attracted in part by a work force that was well-trained in customer contact skills during the 1990s, when credit-card bank MBNA was a major employer in Maine.

Athenahealth has offices outside Boston, Atlanta and Birmingham, Ala., and in India. It set up shop in the former MBNA offices in Belfast in 2007. Today the company has 400 workers in Belfast and held a job fair in Bangor last week to recruit 80 more. Salaries range from $30,000 to $60,000 for associates, plus benefits.

“At the end of the day, it’s all about the workers,” said David Tassoni, Athenahealth’s senior vice president for operations.

The company analyzes and processes billing and medical claims. That requires problem-solving and communication skills, he said.

Skills trump energy costs for the jobs driving Maine’s economy, labor department data show. They also show how energy-intensive jobs have been fading, but not directly because of costs.

Global market forces have been eroding Maine’s manufacturing industries for many years, trends made worse recently by the recession. Wood products jobs fell from 7,865 in 2000, to 4,104 in 2010. Paper manufacturing plunged from 12,847 in 2000, to 7,397 in 2010.

“Production is declining, and that’s true throughout the nation,” said Glenn Mills, chief economist at the state’s Center for Workforce Research.

Mills declined to discuss policy issues around the role of energy and work-force skills and training in job creation, or to comment on the governor’s statement. But he did point to data that highlight where jobs are being created in Maine, and they’re not in industries where energy is a deciding factor.

Professional and business services jobs grew from 52,583 in 2000, to 56,715 in 2010. Jobs in leisure and hospitality are up from 57,845 to 61,547. Hospital employment rose from 26,217 to 34,551 during the period.

The labor department also made projections for net job growth between 2008 and 2018. These are the top five positions: Registered nurse, personal and home care aide, home health aide, food preparation and server, customer service representative.

The department also looked at the fastest projected rate of growth. The top five jobs are: Network systems and data communications analyst, medical scientist, financial examiner, medical equipment repairer and funeral attendant.

‘ONE OF MANY FACTORS’

Many fast-growing jobs are office-based, and energy costs do matter to companies that lease space. It’s a growing issue at buildings heated with oil. Fuel oil has been at record levels — averaging $3.86 a gallon, according to the state’s most recent weekly survey. That’s 24 cents below the national average, but higher than natural gas.

As he travels the state, LePage hears from many business owners upset by high energy costs, according to Adrienne Bennett, his spokeswoman. That feedback has informed his views on how energy influences job creation, she said.

“This is the information coming from the job creators in the state,” she said.

For business owners, questions about utilities now rival those regarding rent, taxes and common-area charges, according to Mark Malone of Malone Commercial Brokers in Portland. Typically, however, energy isn’t the deciding factor for office relocation.

“It’s one of many factors,” he said, “but it’s probably not the one that’s going to make or break it.”

WORKERS ARE KEY

Even for small Maine manufacturers, the picture is more complicated.

ComNav Engineering makes microwave and other filters for business and the military. It uses a lot of electricity, and Martin Geesaman, the president and founder, said he has contemplated relocating out of state. But that would mean losing the technicians and other workers trained over time.

“I really value my employees,” he said. “I use a lot of power, but it’s not worth moving to a different location.”

The 16-year old Portland company is moving, but just down the street. It just bought the former Maine Turnpike Authority headquarters, to have more space and better parking.

Tony Gelardi has been making injection molded products in Maine since 1973, when he co-founded Shape Inc., an audio cassette maker. Today, his Sagoma Technologies has a dozen workers who make packaging for optical discs and other items in Biddeford. The plant uses electricity to melt and reform plastic. Running the machinery all day and night translates into $10,000-a-month electric bills.

Gelardi said he’s frustrated by energy costs and welcomes state efforts to lower them. To cope, meanwhile, he has developed lighter parts, so he can melt less plastic resin. He’s also belatedly signing up with a competitive energy provider, to get a better rate than the state’s standard offer.

Using energy more efficiently is the best way for businesses to compensate for higher prices, said Charles Colgan, a University of Southern Maine professor and former state economist. Maine can’t attract manufacturers that do routine work that can be done more cheaply overseas, he said. Our best bet is high technology and custom work that requires a skilled work force, he said.

When discussing energy and jobs, LePage sometimes tells a story about meeting South Korea’s counsel general last year, and pitching Maine as a good place to build an automobile assembly plant. The official told him that Maine’s beautiful, but its energy costs are too high.

“When you drop your energy, we’ll put plants here,” LePage has said, relating the conversation.

That’s an unrealistic expectation, Colgan said. South Korean automaker Hyundai builds cars in Alabama, and at a sister Kia plant in Georgia. Those states do have lower energy and labor costs. But Maine also has additional liabilities, Colgan said, including our distance from suppliers and inadequate port, rail and highway connections.

“You’d never build an auto manufacturing plant in Maine, not because of our energy costs, but because of our location,” he said. “Energy costs would be way down on the list of problems.”

Staff writer Tux Turkel can be contacted at 791-6462 or

tturkel@pressherald.com

Copy the Story Link

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.