Gale-force winds and heavy rain lashed the Maine coast on Nov. 1, 2013. Power went out in parts of Hancock and Washington counties.

It was a perfect day to stay indoors, and watch history being made in ocean energy.

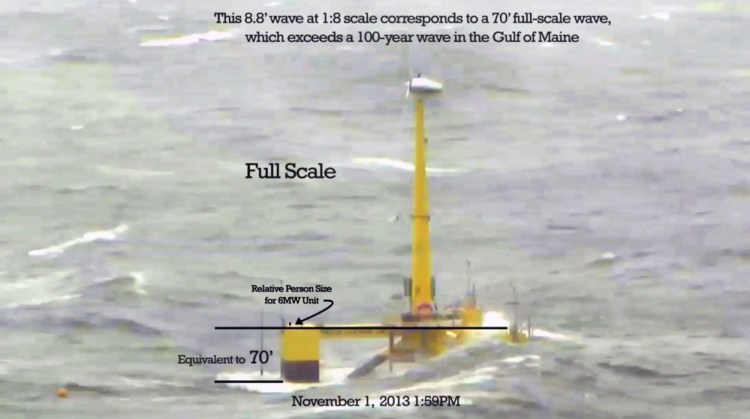

At their computers, University of Maine researchers and their partners were monitoring data streams coming from 60 sensors on the VolturnUS wind turbine, their experimental, floating platform anchored off Castine. On a shoreside video feed, they could see waves nearly 9 feet high washing over the concrete platform, which was one-eighth the size of a full-scale unit. That was the equivalent of a full-size platform bearing the brunt of a 70-foot wave, bigger than any that could be expected in the Gulf of Maine every 100 years.

But what they saw next was even more amazing: The turbine spinning 40 feet above the ocean had a pitch angle of only 5.9 percent, meaning that it was staying nearly vertical, despite the churning sea. That motion measurement mirrored the team’s computer models, vindication that they could predict how the platform would perform far offshore.

“That was the ah-ha moment,” said Habib Dagher, director of the Advanced Structures and Composites Center and the lead researcher on the project.

Dagher and his team made calculated gambles on several innovative strategies – from the unconventional materials used to make the platform and tower, the unusually large scale of the test platform, and the sheltered-yet-stormy location chosen to test them. Those calculations now are paying off.

MOST ADVANCED TECHNOLOGY

Three years later, the university-led consortium known as New England Aqua Ventus has the most advanced floating technology being developed in the United States. Last month, the project was the only floating technology to win a $40 million federal grant, critical to building two full-size platforms for testing off Monhegan Island in 2018. Those platforms would hold 6-megawatt turbines, each with the capacity to power 3,000 average homes.

“Right now, it’s fair to say that the Maine project will be the first floating wind turbine in the United States,” said Walter Musial, manager of the offshore energy program at the federal government’s National Renewable Energy Laboratory in Golden, Colorado.

The government estimates that 60 percent of America’s offshore wind energy potential is in water too deep for steel towers to be buried in the seabed, as is common in Europe. Aqua Ventus offers the promise of tapping that power at a cost that can compete with fossil fuels, by mass-producing dozens of giant platforms and anchoring them far offshore, out of sight but close enough to bring a new, clean energy source to coastal cities. It also could create a new industry to build and service the platforms in Maine.

“The platform has to hold 400 tons 395 feet above the water and float in 70-foot waves during a hurricane,” Dagher said. “That’s what we’re trying to achieve.”

INSPIRED BY CONCRETE

Virtually all of the world’s ocean wind projects are made of steel. But Maine lacks steel mills and iron ore mines. What it does have is limestone deposits and New England’s only cement manufacturer, Dragon Products Co. in Thomaston. It also has a world-class composites center at UMaine that has years of experience developing breakthrough concrete and composite designs, from affordable, quick-build bridges to boat hulls that can handle high-speed stress. That’s where the Aqua Ventus team went for inspiration.

Their design – now being refined for a full-scale model – resembles three, upside-down concrete bridge columns that each will be 120 feet tall. They will be partly submerged and connected by 150-foot-long horizontal beams. The rotor of each wind turbine will spin 395 feet above the sea, turning blades 500 feet in diameter.

The platform will be built and assembled on land and towed to sea, just as the Castine prototype was. Once anchored on site, the hollow beams will be filled with seawater. These and other features pull down the platform’s center of gravity, making it more resistant to wind and wave motion.

“The design is simple to build,” Dagher said. “Bridge contractors can do this, and it can be produced locally. That drives costs down significantly.”

This approach is meant to solve challenges that make offshore wind energy costly to develop.

Steel is more expensive per pound than concrete and has less mass. Steel towers assembled offshore also need special “jack-up” vessels and cranes to lift them. Steel corrodes, unlike concrete. And steel is heavy, compared to the composite fiberglass tower holding the VolturnUS turbine. It’s half the weight of a comparable steel tower.

“Concrete was perceived to have a higher risk initially,” Musial said. “But a lot of those risks have been mitigated by the 1:8 scale project.”

The merits of concrete and composites caught the eye of DCNS Group, a French defense company that has been expanding in marine energy technology and has ocean energy projects in France and Nova Scotia. It has become a partner in the venture.

“From the design viewpoint,” said Frederic Le Lidec, DCNS’s marine renewable energy director, “we have conducted our own extensive due diligence on the VolturnUS hull technology, and reached a very positive conclusion about the quality of the UMaine design work, and potential commercial benefits of the technology.”

SEARCHING FOR BEST SITE

Offshore wind has borrowed a technique from the oil and gas industry to test miniature versions of new structures in wave basins, essentially big swimming pools that simulate ocean conditions. The models typically are built to a 1:50 scale. VolturnUS had a similar 1:50 test, but Aqua Ventus then chose to build an intermediate-scale model and set it out in the real world. No other floating wind project has done that.

“The VolturnUS 1:8 scale experiment off Castine provided very important data to validate the modeling tools and the performance of the design both in operational and extreme storm environments,” Le Lidec said.

Full-size pilot projects rarely experience 100-year weather events, so it’s hard to predict their performance in the worst conditions. The data collected by the 1:8 scale platform, Le Lidec said, can assure investors that the platform will perform at a commercial scale in the nastiest weather.

To find the best site for VolturnUS, researchers used wind- and wave-measuring buoys to study locations along the Maine coast. After a year of data collecting, they settled on a spot off Dice Head in Castine that had a high probability of seeing the desired 1:8 scale waves and wind. The $1 million prototype was built by Cianbro Corp., an Aqua Ventus partner, and towed out in June 2013. The prototype remained in the water for 18 months, during which time the platform and turbine experienced 40 storms with intensities that could be expected within 50 and 500 years. It was a good move to test off Castine, Musial said, instead of the open water off Monhegan.

“They were able to demonstrate a lot more at the site,” he said. “Penobscot Bay was sheltered enough that it didn’t wipe the whole machine out. The design would have been exceeded at Monhegan.”

‘NO ONE TALKED ABOUT CONCRETE’

The Aqua Ventus team now is finalizing the full-scale design package and is on track to gain formal commitments from unnamed investors next year. At the same time, it’s collecting data at the proposed Monhegan test site using a laser technology that can clock wind speeds 395 feet in the air, the hub height of the wind turbines.

While the Aqua Ventus technology has won support from the U.S. government, other floating designs are competing for global attention and investment.

UMaine’s chief rival in the Department of Energy grant competition, Principle Power, failed to win a power contract with a utility in Oregon and was cut from consideration. But the company recently concluded testing a 2-megawatt steel platform called WindFloat off Portugal, and is planning multi-unit floating farms in Europe and Japan.

Statoil, the Norwegian energy company that pulled the plug on a proposed test project in Maine in 2013, is building a 30-megawatt steel wind farm off Scotland.

And recently, floating-wind researchers are developing an interest in concrete. Testing has begun on a hybrid concrete-steel platform in Japan; a concrete design is being built in France and another is proposed in Spain. In a news release last month, the Spanish developers of Windcrete noted that it could be built in dry dock, towed to sea and partially flooded with seawater, avoiding the expense of floating cranes.

These benefits sound familiar to the Aqua Ventus team.

“No one talked about concrete until we put ours in the water,” Dagher said.

Tux Turkel can be contacted at 791-6462 or at:

tturkel@pressherald.com

Twitter: TuxTurkel

Send questions/comments to the editors.

Comments are no longer available on this story