PORTLAND – There was a time, David Munster told me, when TV repairmen didn’t have to be especially delicate.

With the old wood-console TVs that had sturdy cathode-ray picture tubes inside, you could jostle the set a bit in the truck or lay it on its back and expect it to survive. But today, after 38 years in the business, Munster has had to develop a slightly more delicate touch.

“We used to put them in the truck and not worry about them too much. We could be a little bit rougher with them,” said Munster, 58, of Portland. But today, TV screens are a lot more fragile, filled with plasma or LEDs. A bump, jostle or misplaced elbow can result in big problems.

“If the screen cracks, then the whole thing is done. You have to replace it,” said Munster.

I kept this in mind as I helped Munster unload a 42-inch Panasonic LCD TV from a tractor-trailer truck into his Forest Avenue store. We crossed a parking lot covered with ice and snow, in a biting wind.

And the experience confirmed something else Munster told me — that carrying flat-panel TVs all day is an ergonomic nightmare. Unlike carrying old, boxy TVs, you aren’t able to put both your arms in the same place, under the box. With the new, thin TVs, you have one arm underneath and one arm on top, so you’re really stretched out.

“It can really hurt your shoulders after a while,” said Munster.

Munster has seen a lot of changes in the years he’s run his shop. He grew up in the repair business. His grandfather had a radio business beginning around 1940, and his father had TV repair shops until 1973, when Munster took over.

One change, of course, is cost. A major repair job on a new TV — many today cost $1,000 — can be $300 to $600 or so. Because Munster does a lot of component replacement — replacing one small capacitor, for instance, instead of replacing a whole section of them attached to one panel — he can still do some fairly inexpensive repairs, for about $80 or less.

His training has taught him to save all parts, since you never know when they will be needed. So instead of having to buy a whole “board” of components, the way a manufacturer might sell them, he often has single parts in his basement.

When I was with Munster last week, he took off the back of a 42-inch Samsung LCD TV and started to show me why it wasn’t working.

But as he started to talk, I was hypnotized by the hundreds — maybe thousands — of tiny components that filled the back of the set. I thought that because today’s TV sets are thin and sleek they didn’t have much in them, but I found out that is not true.

Munster pointed to tiny computer chips and little battery-size components called capacitors, whose job, he told me, is to store power. A couple of capacitors had gone bad, as evidenced by a small blossom of metal on their tops.

As Munster grabbed some new capacitors — with more storage capacity — he told me that he doesn’t like to skimp on parts, even if they cost more.

“If a product can be made for less money than something else, there’s usually a reason for it,” Munster said. “We try to give people the best-quality part because we want to keep our customers.”

Munster still makes service calls, going to people’s homes to try to fix problems. He and his staff deliver and install the new TVs he sells, as well. He still fixes older TVs — the ones that stick way out in back because they use cathode-ray tubes — and sells used ones. He says a tube TV, after he fixes it, can still last another 15 or 20 years.

“It’s all about cost. If someone only has $50 or $100 to spend, that’s a good way to go,” said Munster.

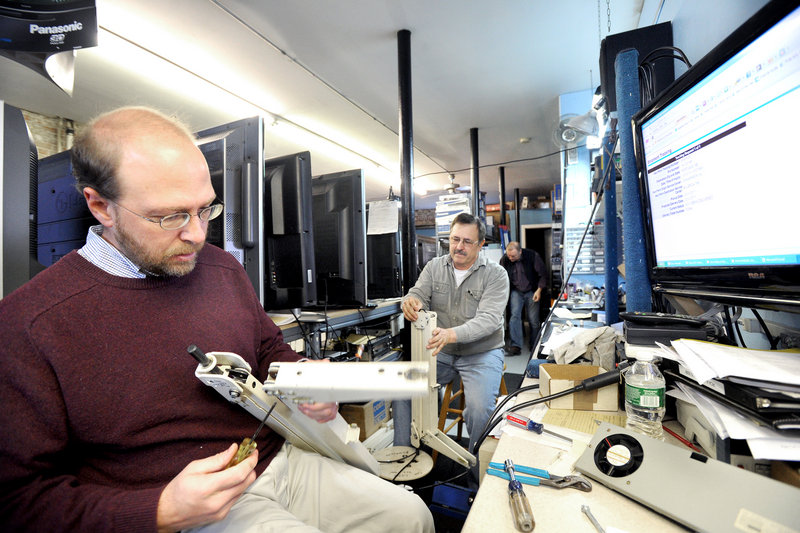

After Munster showed me the bad capacitors, another of his repairmen began replacing them. Munster then began putting new cable wires into some TV swing arms from Mercy Hospital in Portland. This was very basic, mechanical, old-fashioned repair work.

Munster and I sat on stools in his cramped workbench space, each with one of the heavy metal swing arms on our lap. Munster showed me a pin in the arm and told me not to remove that, or else the springs in the arm might cause it to whack me. He then showed me where to cut the cable with some clippers and how to take it out of the arm.

Then he gave me new cable and showed me how to string it through the arm. A couple of times the wire got stuck and I tried to jam it through with a screwdriver. It took a few minutes, but I finally got it through.

When it came time to put on the cable ends — the little metal pieces that screw into the back of your set — Munster told me to put the little plastic sleeves back on the ends of the cable. Little plastic sleeves?

“Remember those little pieces of plastic that were on the cable when you started?” asked Munster.

“Oh, I threw those away,” I said.

Luckily, the wastebasket was still at my feet. I fished the pieces out and finished the job.

While we worked on the swing arms, Munster also answered questions from his son, Ryan, about what to do for a customer who wanted to upgrade to a larger TV. They talked about the price, when it might be installed, what larger TVs they had to sell him. He talked with other employees about calls for service, and when he might get to them.

Plus, he had just brought five new TVs into the store and was planning at some point to put them on display, probably on wall mounts.

“There’s a lot of different parts to it, and I like all of it,” said Munster.

Staff Writer Ray Routhier can be contacted at 791-6454 or at:

rrouthier@pressherald.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.